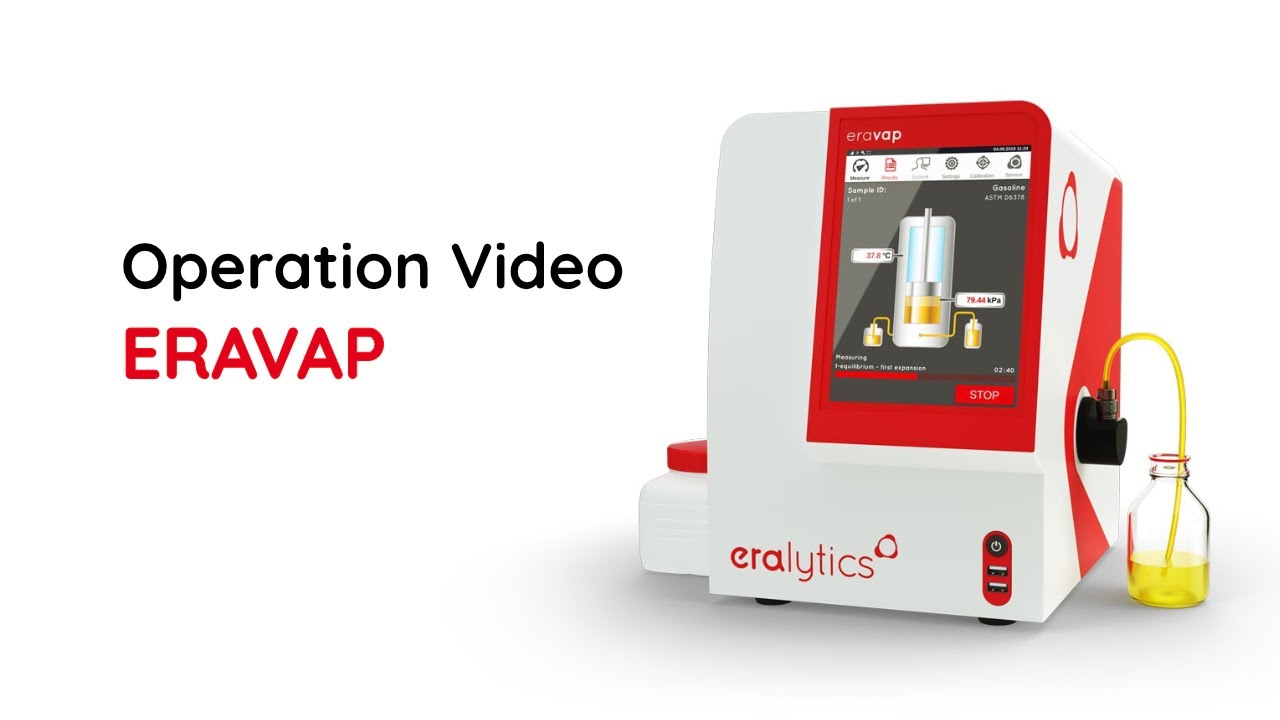

Vapor Pressure Testing at its Best

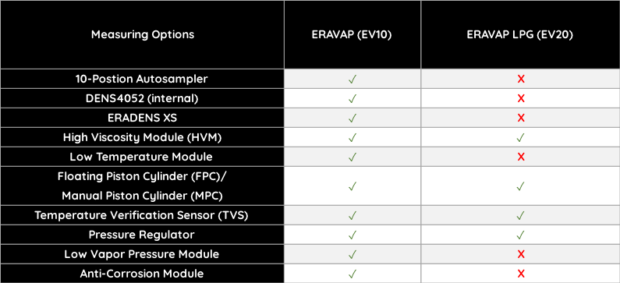

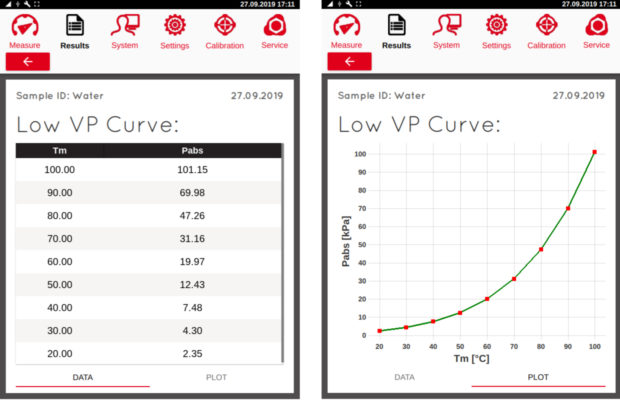

With unmatched precision, speed and versatility ERAVAP is the instrument of choice for vapor pressure testing of e.g. gasoline, crude oil, LPG, solvents, fragrances or aqueous solutions in full compliance with the latest international standards. With eralytics ultra-light temperature-controlled U-tube density meter module DENS4052 (patent), ERAVAP offers even more: simultaneous measurement of vapor pressure and density in a single, portable analyzer.