LPG Vapor Pressure Testing at its Best

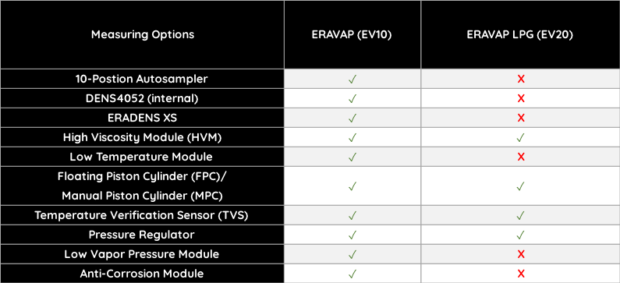

For LPG vapor pressure testing eralytics increased the standard operating range of the ERAVAP to up to 2000 kPa. ERAVAP LPG is fully compliant with ASTM D6897 and covers a temperature range of -20 °C to 120 °C. Additionally, ERAVAP LPG can measure gasoline and crude oil according to the most common standard test methods (ASTM D5191, D6377, D6378, D5188, EN 13016).