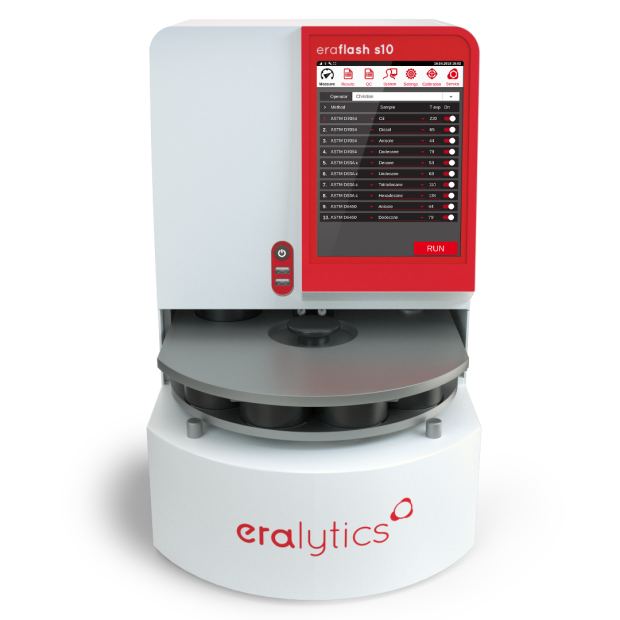

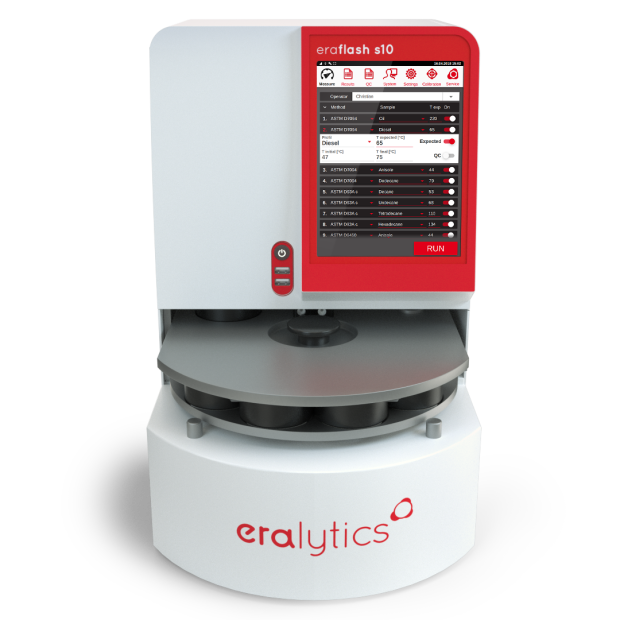

eraflash s10

The safest flash point autosampler.

eralytics’ flash point autosampler eraflash s10 combines the safest measurement with a 10-position autosampler. The inherently safe CCCFP methods ASTM D7094, ASTM D6450, and IP620 are ideal for unattended measurements. ERAFLASH S10 ignites the vapors of 1-2 ml of the sample inside a closed chamber and measures according to the pressure increase.

360° View

Autosampler for flash point testing

eraflash s10 is the first 10-position autosampler for flash point testing. It uses the inherently safe methods ASTM D7094, ASTM D6450, and IP620. With a low sample volume of only 1-2 ml and the continuously closed sample cups, they are ideally suited to build a completely safe autosampler for flash point testing. eraflash s10 is the perfect solution for high-throughput laboratories and takes up very little laboratory space.

This makes ERAFLASH S10 the ideal analyzer for unattended flash point testing.

Cost-efficient and fast flash point testing

When looking at valuable products, especially with small batch sizes, flash point testing using the well-known Pensky Martens principle can consume a significant amount of sample, thus leading to high analytical costs. When performing flash point testing according to ASTM D7094 and IP620 just 2 ml of the sample are needed. ASTM D6450 reduces this volume even further to 1 ml.

eraflash s10 is therefore a welcome addition to testing labs handling large amounts of costly samples every day. This includes fragrances, paints, and varnishes producers.

Peltier Boost Technology®

Similar to eralytics’ single position flash point tester the patented PBT – Peltier Boost Technology® allows flash point testing below 0 °C (32 °F) and above 200 °C (392 °F) with a single instrument. PBT separates the Peltier elements during the heat up at 100 °C shielding them from higher temperatures that would normally harm them. During the cool down, however, they can be used for active cooling starting at 200 °C and thus reduce the turnaround time significantly. PBT also facilitates the same temperature range of -25 °C (-13 °F) to 420 °C (788 °F) of our single position flash point tester in an autosampler for flash point testing.

scroll to see more images

gallery controls

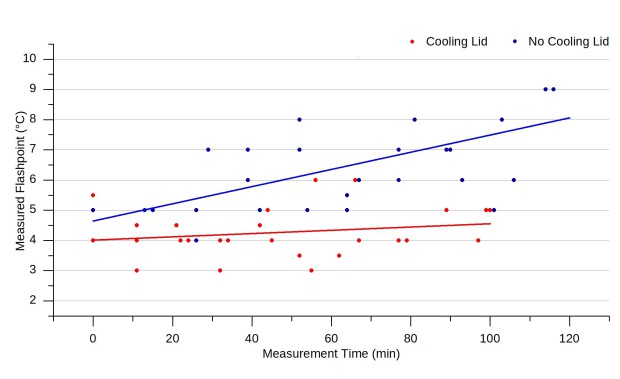

A cooling lid for shorter turnaround times

eraflash s10’s optional cooling lid is an unsurpassed benefit, especially in applications that involve highly volatile samples. The lid keeps the pending samples at a stable temperature, which makes volatile compounds far less likely to evaporate before their measurement starts. Therefore, results are more precise and more reliable. With pre-cooled sample cups cooling during the measurement can be less intense, which results in shorter turnaround times.

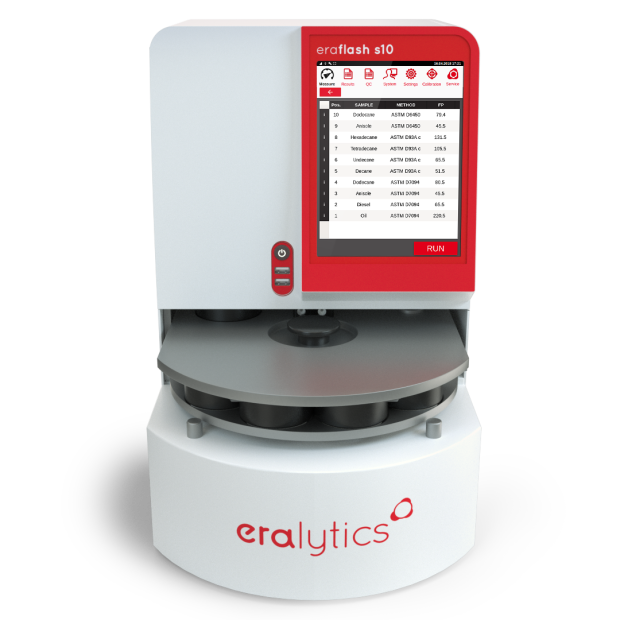

Measurement procedure

Just four easy steps are required for an unattended safe and fast flash point testing at maximum precision:

- Enter sample IDs and operator name

- Select the measurement standards and add additional parameters (e.g. expected flash point)

- Fill up to 10 sample cups with samples, place the sample cups on the carousel and close the cover plate

- Press the RUN button

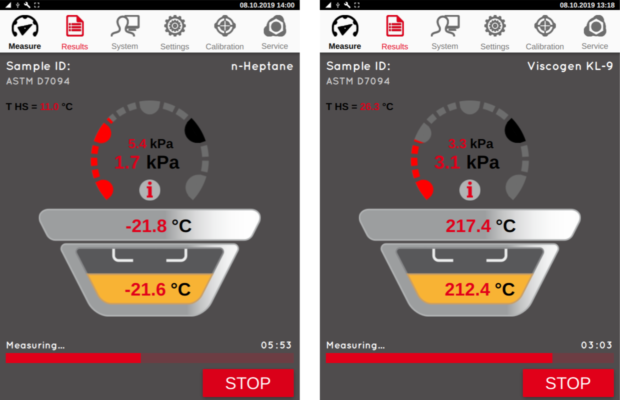

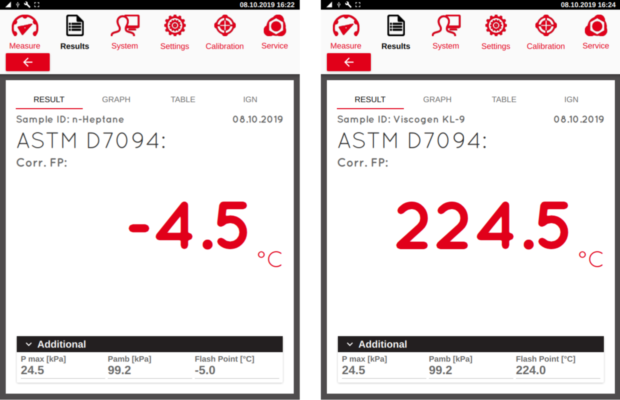

During flash point testing the instrument visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. Additional information about the currently measured sample, as well as finished and still samples to be measured are displayed. After the measurements the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5°C. All results will be saved in the corresponding result file.

scroll to see more images

gallery controls

eraflash s10 feature video

- High throughput with the 10-position autosampler

- Inherently safe with no open flame

- Only a very low sample volume of 1-2 mL needed

- Takes up very little laboratory bench space

- Fully compliant with ASTM D6450, ASTM D7094, and IP620

- Measurement of fuels, lubricants, fragrances, flavors, paints, …

eraflash s10 operation video

Watch this video to get an overview on the standard operation of eraflash s10: From installation to measurement and some extended measuring options.

Technical Specifications

- Standard Test Methods

- ASTM D6450, D7094, IP 620, SH/T 0768

- Fuel Specifications (ASTM D7094)

- ASTM D396, D975, D1655, D2880, D3699, D7467, D7566

- Approved by

- NATO, RCRA, US DOT, US NAVY

- Special Test Methods

- Fast screening test method SCAN for unknown samples, Flash / No Flash tests, freely programmable test methods

- Correlation Test Methods

- Pensky Martens Closed Cup: ASTM D93; EN ISO 2719; DIN 51758; IP34; JIS K2265

TAG Closed Cup: ASTM D56

Abel Pensky Closed Cup: ISO 13736; IP170

Small Scale Closed Cup: ASTM D3828; EN ISO 3679, EN ISO 3680 - Sample Handling

- 10-position autosampler

- PBT – Peltier Boost Technology®

- High speed heating & cooling

-25 °C to 420 °C (-13 °F to 788 °F) with a single analyzer - CPT – Contamination Prevention Technology™

- Advanced electrode protection and self-cleaning ignition system to minimize cleaning and maintenance

- Combustion Graphics™

- Display of combustion characteristics for contamination analysis

- QC Mode

- Built-in quality control mode including on-screen QC charts

- Cooling Lid Temperature

- 5 °C to 30 °C (optional)

- QuickCal™

- In-situ calibration with eralytics unique calibration cups without the need of dismantling the instrument

- Fuel Dilution Program

- Automatic fuel dilution measurement for the analysis of used engine oils

- Temperature Range

- 0 °C to 200 °C (32 °F to 390 °F) stand alone

down to -25 °C (-13 °F) with external cooling

up to 420 °C (788 °F) with optional High Temperature Module - Temperature Stability

- 0.1 °C (0.2 °F)

- Unattended Sample Throughput

- 10 loaded samples within approximately 45 minutes (depending on temperature range)

- Sample Volume

- 1 mL (ASTM D6450), 2 mL (ASTM D7094)

- Sample Cups

- Nickle plated aluminium, stainless steel cups available upon request

- Result Database

- Over 100 000 detailed test reports stored in internal memory

- Alarm Tracking

- All alarm messages are stored in the database together with the result

- Display

- Industry proven 8.4″ color touchscreen

- Languages

- English, German, French, Spanish, Russian, Chinese

Additional langages available upon request - Interfaces

- Built-in PC with Ethernet, USB and RS232 interfaces

Direct LIMS connectivity and output to printer or PC

Optional input by external keyboard, mouse and barcode / QR-code reader

Wifi via external USB dongle - Remote Control

- Remote service capability via Ethernet interface

- PC Software

- ERASOFT RCS – remote control Windows® software for multi-instrument remote control, convenient data transfer andresult analysis

- Operating Conditions

- Temperature range 10 °C to 40 °C

Humidity up to 90% RH, non-condensing - Power Requirements

- Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available - Dimensions & Weight

- (W x D x H) = 29.5 x 36.9 x 45.4 cm (11.6 x 14.5 x 17.9 in) / 18.1 kg (39.9 lb)

Downloads

- eraflash s10 Brochure English

- eraflash Series Portfolio Brochure

- Application Note: eraflash empowered to specify jet fuel

- Application Note: eraflash – Efficiency through maximum safety and measuring speed

- Application Note: Flash Point determination in Food, Flavors and Fragrances

- Application Note: eraflash and ASTM D7094 The world’s most precise flash point tester

- Article on “ASTM D7094 – Modified Continuously Closed Cup Flash Point Standard Accepted as a Safe Alternative Method in Various Fuel Specs”

- Datasheet: erasoft RCS English