eralab OCM

The solution for oil condition monitoring.

eralab OCM is a complete oil analysis platform which supports companies in predictive and proactive maintenance strategies by providing valuable insights into equipment health and lubricant condition. This is done by analyzing and evaluating the three critical oil condition categories contamination, wear and oil composition. Using eralab OCM reduces expensive down times as well as lube oil changes and significantly extends machine lifetime.

The Key to Machine Health

Proper lubrication is essential for the function and longevity of any machine. To determine whether your oil still performs according to specifications, several critical key oil condition categories must be monitored. These categories are:

- Contamination

Detects the quantity of particles and its origin, water, fuel, or other impurities compromising oil quality. - Wear

Indicates early signs of component degradation in gear boxes, bearings, pistons, etc. through analyzing metallic debris. - Oil Composition

Detection of oil composition changes even if the oil looks “clean”, monitoring of viscosity, acidity, oxidation, and additive levels, etc. and helps to evaluate oil health and operational conditions.

Changes to any of these categories enable maintenance teams to identify early problems, take immediate action and prevent serious damage or unexpected downtime.

eralab OCM Pro

eralab OCM Pro provides a comprehensive OCM solution, monitoring all three critical categories like contamination, wear and oil composition.

eralab OCM Pro is tailored to give you clear answers to key questions such as:

- Is any part of my machine beginning to fail based on the wear metals found?

- Are there any signs of wrong operation conditions?

- What is the chemistry of wear and contamination?

- Did I use the correct oil when refilling?

- Has the composition of the oil changed?

- Is my oil clean enough for operation?

- Is my oil wet?

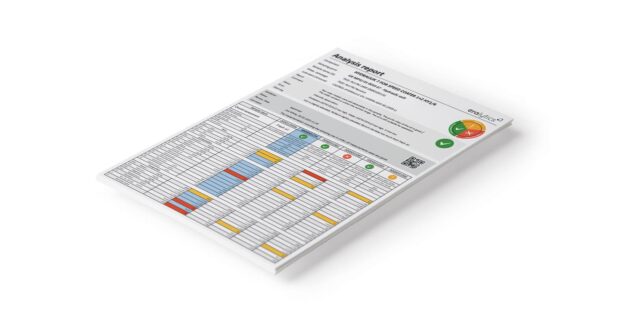

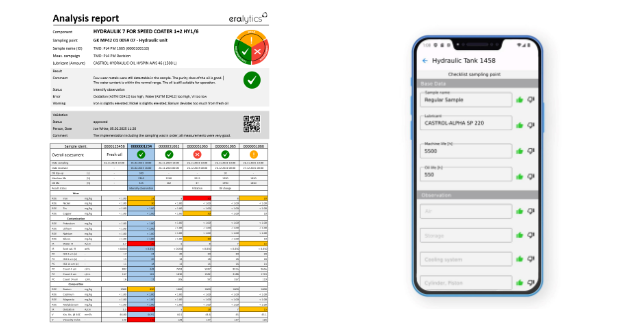

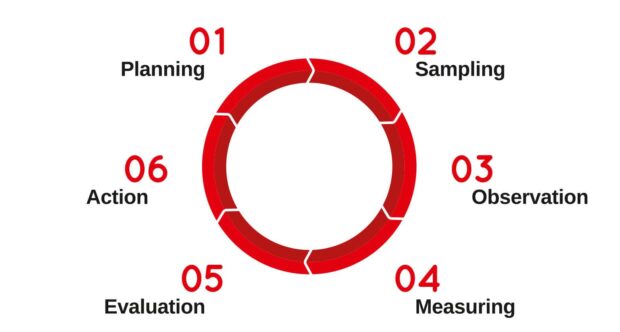

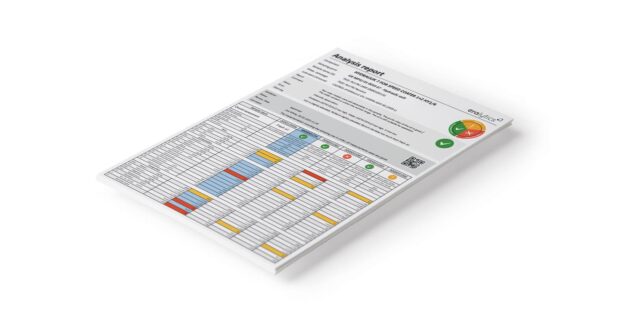

After taking four simple measurements, the data is sent to the erasoft OCM. The software then analyses the results, triggers alarms and warnings based on the condition of the oil and generates a report on its health as well as, providing recommended maintenance actions for the maintenance team.

eralab OCM Pro’s extensive analysis of the oil reduces risk of unplanned downtime, extends oil drain intervals and maximizes machine lifetime as well as enables optimization of local maintenance plans.

eralab OCM Pro consists of erasoft OCM with the following analyzers: eraspec oil + eraoil + eravisc X + eracount xs

scroll to see more images

gallery controls

eralab OCM Basic

eralab OCM Basic provides an effective OCM solution that is focused on two oil condition categories: contamination and oil composition. This package is particularly well-suited for applications where wear monitoring is not a primary concern.

eralab OCM Basic is tailored to give you clear answers to key questions such as:

- Did I use the correct oil when refilling?

- Are there any signs of wrong operation conditions?

- Has the composition of the oil changed?

- Is my oil clean enough for operation?

- Is my oil wet?

Similar to eralab OCM Pro, eralab OCM Basic only requires three simple measurements before generating a report on oil health, including all the relevant results and recommended maintenance actions. It is therefore the perfect starting point for oil condition monitoring, giving you the essential tools to avoid unplanned downtime and to extend drain intervals.

eralab OCM Basic consists of erasoft OCM with the following analyzers: eraspec oil + eravisc X + eracount xs

scroll to see more images

gallery controls

eralab OCM: Your all-in-one partner for oil condition monitoring

Whether you are new to OCM, currently outsourcing your OCM tasks, or an experienced professional, eralab OCM is your flexible, comprehensive solution for unmatched reliability, transparency, and control.

- Easy to use for beginners.

Starting from scratch? No worries – eralab OCM analyzers simplify every step and enable you to gain actionable, results-oriented insights in minutes. All without complexity. - Effortless switch to In-house testing.

Implement it today and take control tomorrow with our reliable analyzers that allow you to integrate oil analysis into your business so you can actively make informed decisions instead of passively receiving data. Fast and straightforward. - Next level OCM testing professionals.

With eralab OCM, you can take your OCM practice to the next level—with smoother workflows, accurate diagnoses and seamless integrations. Groundbreaking for experienced users. - Maximum flexibility: Enhance eralab OCM Basic with eratest ferro for fast ferrous debris checks, eraflash X for fuel dilution, or integrate third-party analyzers to expand capabilities. Flexible configurations ensure eralab OCM works your way.

- Lab grade accuracy. All eralab OCM analyzers are produced by eralytics and are known for their precision and reliability.

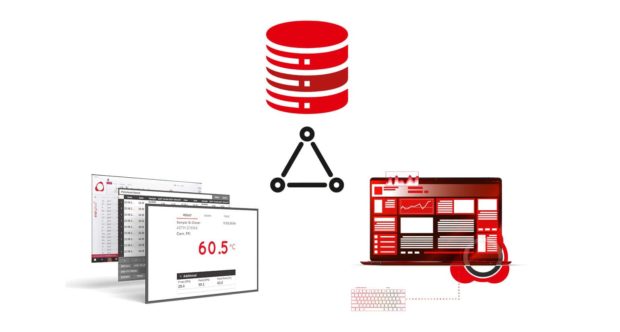

Software solution erasoft OCM

erasoft OCM is the core software of eralab OCM. It fully covers and digitalize every step of the OCM process, from asset management and sampling planning to data analysis, action tracking, and maintenance recommendations. It generates clear reports that highlight warnings and errors and provides maintenance recommendations based on the test results.

Based on the customers specific needs, the package can flexibly be configured to fit both the technical requirements and the budget.

Get more detailed information on erasoft OCM software >>

scroll to see more images

gallery controls

eralab OCM Analyzers

| Category | Parameter | eraoil | eracount xs | eravisc X | eraspec oil |

|---|---|---|---|---|---|

| ASTM D6595 | ISO 4406 | ASTM D445 corr. | ASTM E2412 | ||

| Contamination | Particle count ISO codes | x | |||

| Boron, Calcium, Sodium, Lithium, Potassium, Silicon | x | ||||

| Water | x | ||||

| Wear | Copper, Silver, Chromium, Titanium, Aluminum, Magnesium, Nickel, Iron, Manganese, Lead, Tin, Molybdenum, Cadmium, Vanadium | x | |||

| Composition | Viscosity 40 °C & 100 °C & VI | x | |||

| Total Acid Number (TAN) | x | ||||

| Total Base Number (TBN) | x | ||||

| Oxidation, Nitration | x | ||||

| Additives (Phenol, Amine, Antiwear, etc.) | x | ||||

| Boron, Magnesium, Calcium, Barium, Zinc, Molybdenum, Phosphorus | x |

eralab OCM: Features at a glance

eralab OCM offers a range of easy to use, rugged and accurate oil analyzers. Paired with the advanced erasoft OCM software solution – the heart of eralab OCM – it facilitates the development of a successful in-house oil condition monitoring program. With the eralab OCM analyzer portfolio, eralytics offers the right solution for every stage of in-house oil condition monitoring.

Downloads

- eralab OCM Brochure English

- eraspec oil Brochure English

- eraoil Brochure English

- eratest ferro Brochure English

- eracount xs Brochure English

- eravisc X Brochure English

- eraflash X Brochure English

- Whitepaper: Getting Started with In-house Oil Condition Monitoring

- Case Study Oil Condition Monitoring – A practical and effective solution

- Oil Condition Monitoring (OCM) with FTIR spectroscopy – Comparison, challenges and solutions