eraoil

The stand-alone RDE-OES spectrometer.

eraoil is the first and most advanced stand-alone rotating disc electrode spectrometer analyzing wear metals, additives, and contaminants in all kinds of operating liquids, like lubricating oils, heavy fuel oil, fuels, coolants, process water, etc. Up to 32 elements are measured fully automatically within 30 seconds. eraoil’s high-end CMOS detector in combination with the automatic background correction allow for a sub-ppm detection limit (LOD) for most elements.

360° View

Standards

Smallest footprint with built-in PC

eraoil’s unique stand-alone design offers a rugged all-in-one package for operation even in the smallest on-site testing labs. It comes with a built-in 10” color touchscreen and a PC. Even an electrode sharpener and an automatic ventilation system are integrated into the eraoil. Still, it is the RDE-OES analyzer with the smallest footprint on the market. eraoil is very easy to use even for untrained operators. The automated measuring procedure follows simple steps and is therefore perfect for on-site inspection: Just fill the sample cup, close the door, and push the start button. The elemental concentration is available immediately.

High-precision oil and fuel analysis

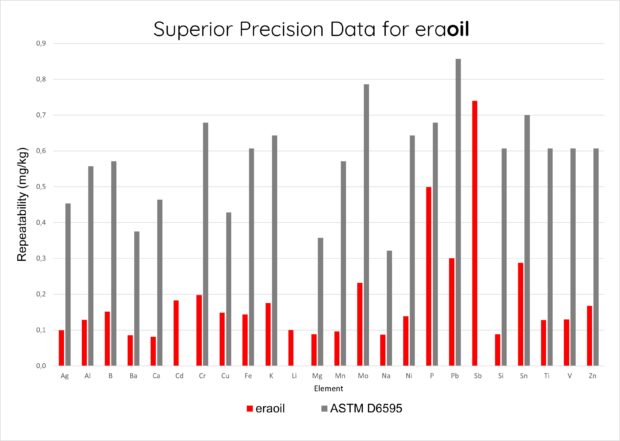

eraoil is fully compliant with ASTM D6595 (oil) and ASTM D6728 (fuel). ASTM D6595 is the standard for identifying wear metals and contaminants in used lubricating oils and used hydraulic fluids by rotating disc electrode optical emission spectrometry. For determinating contaminants in gas turbine and diesel engine fuel, ASTM D6728 is the standard of choice. To protect finished fuels against trace contamination eraoil is available with the special Low Detection Fuel Module to detect e.g. Potassium, Lithium, Sodium and Vanadium at LOD levels of as low as 0.1 ppm.

scroll to see more images

gallery controls

Applications for the spectrometer eraoil

Multi-elemental analysis is the core of in-service oil analysis. Thus eraoil is the perfect solution for wear metal analysis of lubricants from engines, transmissions, hydraulic systems and gears boxes. The fast and easy elemental analysis brings clear advantages for the operation of any commercial means of transport or machines in the industrial environment. This solution also offers clear added value for other applications such as coolants, metal working fluids, or any other process fluids.

Your features at a glance

- Analyzing wear metals, contaminants, and additives in lubricating oils and hydraulic fluids according to ASTM D6595 and contaminants in gas turbine and engine fuel according to ASTM D6728

- Up to 32 elements in 30 seconds with sub-ppm LOD

- Stand-alone design with built-in PC, touchscreen, sharpener & ventilation

- Smallest and most rugged housing for lab and on-site applications

Wear metals and contaminants

| Element | Lubricant ASTM D6595 | Lubricant Ext. Element ASTM D6595 | Lubricant Ext. Range ASTM D6595 | Fuel ASTM D6728 | Low Detection Fuel | Coolant | Water |

|---|---|---|---|---|---|---|---|

| Silver (Ag) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 10 | |||

| Aluminium (Al) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Arsenic (As) | 0 – 100 | ||||||

| Boron (B) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 10 | ||

| Barium (Ba) | 0 – 1000 | 0 – 1000 | 0 – 6000 | ||||

| Bismuth (Bi) | 0 – 1000 | 0 – 1000 | 0 – 1000 | ||||

| Calcium (Ca) | 0 – 1000 | 0 – 1000 | 0 – 6000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Cadmium (Cd) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 10 | |||

| Cerium (Ce) | 0 – 100 | ||||||

| Cobalt (Co) | 0 – 100 | 0 – 10 | |||||

| Chromium (Cr) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 10 | |

| Copper (Cu) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Iron (Fe) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Indium (In) | 0 – 1000 | 0 – 1000 | 0 – 1000 | ||||

| Potassium (K) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 1000 | 0 – 10 |

| Lithium (Li) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | ||

| Magnesium (Mg) | 0 – 1000 | 0 – 1000 | 0 – 6000 | 0 – 1500 | 0 – 300 | 0 – 50 | 0 – 10 |

| Manganese (Mn) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 10 | |

| Molybdenum (Mo) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 500 | |||

| Sodium (Na) | 0 – 1000 | 0 – 1000 | 0 – 6000 | 0 – 1000 | 0 – 100 | 0 – 1000 | 0 – 10 |

| Nickel (Ni) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 10 | |

| Phosphorus (P) | 0 – 1000 | 0 – 1000 | 0 – 6000 | 0 – 2500 | 0 – 10 | ||

| Lead (Pb) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Antimony (Sb) | 0 – 1000 | 0 – 1000 | 0 – 1000 | ||||

| Silicon (Si) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | 0 – 500 | 0 – 10 |

| Tin (Sn) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 10 | |||

| Strontium (Sr) | 0 – 100 | ||||||

| Titanium (Ti) | 0 – 1000 | 0 – 1000 | 0 – 1000 | ||||

| Vanadium (V) | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 1000 | 0 – 100 | ||

| Tungsten (W) | 0 – 100 | ||||||

| Zinc (Zn) | 0 – 1000 | 0 – 1000 | 0 – 6000 | 0 – 1000 | 0 – 100 | 0 – 50 | 0 – 10 |

| Zirconium (Zr) | 0 – 100 | ||||||

| Total | 26 | 32 | 26 | 15 | 15 | 13 | 19 |

Technical Specifications

- Available Test Methods

- ASTM D6595: Wear metals, contaminants, and additives in used lubricating oils and hydraulic fluids

ASTM D6728: Contaminants in gas turbine and engine fuel - Correlation to

- ASTM D5185 (ICP-AES)

- Spectrometer Type

- Rotating Disc Electrode Spectrometer (190 – 810nm)

Thermally stabilized Paschen-Runge mounting with CMOS detectors - Measurands

- Elemental concentrations in ppm (mg/kg)

- Applications

- Determination of additives, wear metals, and contaminants in lubricating oils,

hydraulic fluids, gas turbine & diesel engine fuel, heavy fuel oil (HFO), crude oil,

glycol coolants, process water, mineral water, and grease - Analytical Range

- Simultaneous measurement of up to 32 elements in 30 seconds with a sub-ppm detection limit (LOD) for most elements incl. automatic background correction

- Calibration

- Factory calibrated for 26 elements

Optional calibration for up to 32 elements - Sample Volume

- 2 mL; no solvents, reagents or gases are needed, no cleaning of cell window

- Operating Conditions

- 0 °C to 40 °C (32 °F to 104 °F)

Up to 90% humidity, non-condensing - Fully Integrated Stand-Alone Design

- Built-in electrode sharpener and ventilation system

Industry-proven multilingual 10” color touchscreen

Built-in PC with Ethernet, USB, and RS232 interfaces

Optional connection of a monitor and data input by external keyboard, mouse, or barcode reader - Software

- Windows® software for convenient data transfer, viewing spectra, and result analysis

- Result Database

- Over 100,000 detailed test reports and spectra storable in internal memory

- Dimensions & Weight

- (W x D x H) = 36.0 x 66.0 x 69.5 cm (14.2 x 26.0 x 27.4 in) / 85 kg (187 lb)

- Power Requirements

- 90 – 270 V, AC 50/60 Hz, 500 W

- Recommended Consumables for 1000 Tests

- EOL01 – A001 graphite discs (1000 pcs)

EOL01 – A002 graphite electrodes (100 pcs)

EOL01 – A003 2 ml sample cups (1000 pcs)