eravap for lpg

The LPG vapor pressure tester.

For LPG vapor pressure testing eralytics increased the standard operating range of the eravap to up to 2000 kPa. eravap for lpg is fully compliant with ASTM D6897 and covers a temperature range of 0 °C to 120 °C. Additionally, eravap for lpg can measure gasoline and crude oil according to the most common standard test methods (ASTM D5191, D6377, D6378, D5188, EN 13016).

360° View

Vapor pressure testing of LPG

Information on the vapor pressure of LPG is important for the proper choice of storage tanks and shipping vessels. It is mainly measured for safety reasons that the maximum design pressure of storage and handling systems isn’t exceeded under normal operating conditions. The vapor pressure of LPG can also give insights into the initial evaporation under extreme low temperature conditions.

Maximum flexibility with ASTM D6897

ASTM D6897 can be used to measure the vapor pressure of LPG in the temperature range of 37.8 °C to 70 °C. It covers a vapor to liquid ratio of 0.1:1 to 4:1. The maximum vapor pressure is 3500 kPa. However, the precision statement of a repeatability of 7.4 kPa was only determined in the range of 300 kPa to 1463 kPa.

ASTM D6897 is used to specify the LPG vapor pressure according to ASTM D1835. The vapor pressure of butane must not exceed 483 kPa and the one of propane must be below 1434 kPa according to ASTM D1835 measured at 37.8 °C and a vapor to liquid ratio of 0.5:1.

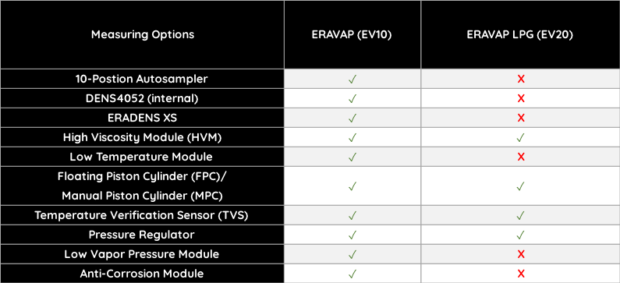

eravap – Unique measuring options

The vapor pressure tester eravap is available in two models. eravap (EV10) for vapor pressure testing of all kinds of liquids up to a max. vapor pressure of 1000 kPa (145 psi) and eravap for LPG (EV20) for vapor pressure testing of LPG’s featuring an extended pressure range of up to 2000 kPa (290 psi). To complete your range of applications, eralytics offers a variety of unique measuring options for both eravap models. Get an overview of the unique measuring options of ERAVAP here >>

LPG configuration

To cover the extended vapor pressure range needed for LPG vapor pressure testing, eravap for lpg is equipped with a dedicated pressure sensor for applications up to 2000 kPa. This adds enough safety margin and allows to test the vapor pressure of LPG even at elevated temperatures.

eravap for lpg covers a pressure range of 0 kPa to 2000 kPa and a temperature range of 0 °C up to 120 °C, V/L ratios down to 0.02:1 and up to 4:1 are possible. eravap for lpg offers a repeatability of r ≤ 2.0 kPa (0.29 psi) for Propane at 37.8°C, clearly outperforming the requirements for ASTM D6897.

In addition it is equipped with a quick-fit inlet system which allows to connect pressurized cylinders with ease.

Technical Specifications

- Available Test Methods

- ASTM D5188, D5191, D6377, D6378, D6897; EN 13016-1, EN 13016-2, EN 13016-3; IP 394, IP 409, IP 481; JIS K 2258-2; GB/T 11059, SH/T 0769, SH/T 0794, SN/T 2932; GOST R 52340; TVP

freely programmable methods

EPA / CARB / US Military & NATO reference methods, TVP measurement

VP-V/L Speed TestTM – Combined T(V/L) and vapor pressure measurement - Correlation to…

- ASTM D323, D1267, D2533, D4953, D5190, D5482

- Fuel Specifications

- ASTM D910, D1655, D1835, D4814, D6227; EN 228

- Temperature Range

- 0 °C to 120 °C (32 °F to 248 °F) with Peltier technology. No external cooling is required.

-20 °C to 120 °C (-4 °F to 248 °F) with additional low-temperature upgrade (EV01-COOL). External cooling is required.

Extrapolated range: -100 °C to 300 °C (-148 °F to 572 °F) - Temperature Stability

- 0.01 °C (0.02 °F)

- Pressure Range

- 0 kPa to 2000 kPa (0psi to 290 psi)

- Pressure Units (selectable)

- hPa, kPa, psi, mmHg, Torr, at, atm

- Pressure Resolution

- 0.01 kPa (0.0014 psi)

- Vapor / Liquid Ratio

- Variable from 0.02/1 to 100/1

Single-, multi-point and curve measurements - Precision

- Repeatability: r ≤ 2.0 kPa (0.29 psi) / Propane at 37.8°C (ASTM D6897)

Reproducibility: R ≤ 4.0 kPa (0.58 psi) / Propane at 37.8°C (ASTM D6897) - Available Extension Modules

- EV01-COOL: Low temperature module (-20 °C – 120 °C / -4 °F – 248 °F)

EV01-VISC: High viscosity module (Heated inlet and outlet up to 70 °C / 158 °F) - Sample Introduction

- Automated via built-in piston

Automated sample filtration through a reuseable 80 µm mesh filter

No external vacuum pump is required - Sample Volume

- 1 mL (2.2 mL per rinsing cycle)

- Measurement Time

- 5 minutes for a standard measurement

- Cleaning

- By next sample or solvent

- Measuring Chamber

- Nickel-plated aluminum chamber

- Display

- Industry proven 8.4” color touch screen

- Languages

- English, German, French, Spanish, Russian, Chinese, Japanese, Greek, Turkish

Additional langages available upon request - Interfaces

- Built-in PC with Ethernet, USB and RS232 interfaces

Wifi via external USB dongle

Direct LIMS connectivity via LAN, output to printer or PC as CSV or PDF

Optional input by external keyboard, mouse and barcode reader - Remote Control

- Remote service capability via Ethernet interface

- PC Software

- erasoft RCS – remote control Windows® software for multi-instrument remote control, convenient data transfer, viewing spectra and result analysis

- Result Database

- Over 100,000 detailed test reports stored in internal memory

DVPE, RVPE, PABS, PGAS, PTOT, ASVP & AVP

Results can be marked for hazy appearance

Graphical view of curve measurements - Alarm Tracking

- All alarm messages are stored in the database together with the result

- Automated Calibration Routine

- 10-point probe offset correction table, calibration history tracking, substance calibration, self-diagnostics

- Operating Conditions

- Temperature range 0 °C to 50 °C

Humidity up to 90% RH, non-condensing - Power Requirements

- Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available - Model Number

- EV20

- Dimensions & Weight

- (W x D x H) = 29.1 x 32.9 x 34.8 cm (11.5 x 12.9 x 13.7 in) / 9.1 kg (20.1 lb)