eravap for crude oil

The crude oil vapor pressure tester.

eravap for crude oil is the leading solution for high precision vapor pressure and density (ASTM D4052) testing of live and dead crude oils according to ASTM D6377, IP481 and GOST 52340. Its unique cell design allows high shaking speeds ensuring unrivaled accuracy and short measuring times. Additionally, special V/L ratio measurements, including the TVP (True Vapor Pressure) method are available.

360° View

Crude oil vapor pressure testing

Vapor pressure of crude oil is a key parameter when planning the transportation of crudes through different climate zones. When performing crude oil vapor pressure measurements one has to bear the actual ambient conditions during transportation in mind. Is the crude transported in rail cars the headspace is approximately 5% where as a floating roof-top tank has nearly no headspace at all. This is important since the vapor to liquid ratio (V/L) and the storage temperature are highly influencing the vapor pressure of crude. This is especially true for live crude oil which still contains high amounts of volatile light ends.

2-in-1: Vapor pressure and density

eravap is the only vapor pressure tester on the market that can be equipped with the optional density meter module DENS4052, fully compliant to ASTM D4052 & ISO 12185 (r = 0.0001 g/cm³). This allows for a simultaneous density and vapor pressure measurement of crude oil. Additionally, the density module can be combined with a pressurized filling system (FPC/MPC), making it uniquely convenient for the testing of volatile crude oils.

scroll to see more images

gallery controls

Pressurized sampling solutions

Measuring live crudes containing high amounts of volatiles requires the use of a pressurized sampling system, such as eralytics newly developed manual piston cylinder eravap MPC (ASTM D8009) or standard FPC floating piston cylinders (ASTM D3700). If such crudes are measured from an open bottle, most volatiles will be lost, giving wrong VP results. For highly pressurized sampling eralytics special pressure regulator can be attached directly to eravap .

scroll to see more images

gallery controls

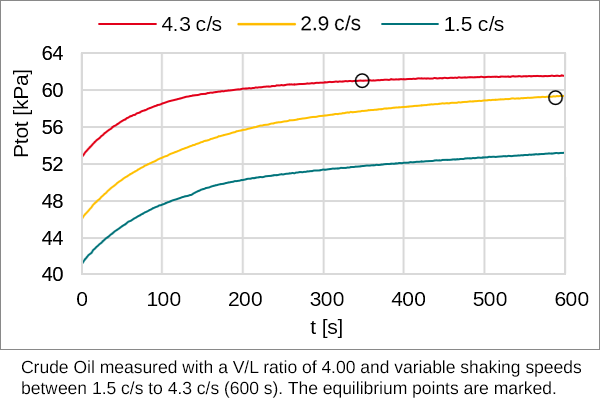

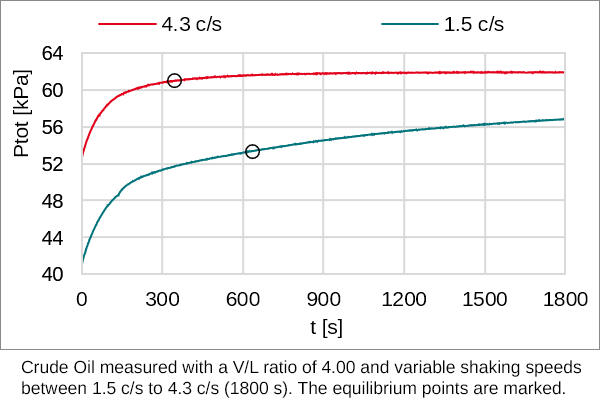

High performance cell shaking technology

Crude oil properties like viscosity play an important role in vapor pressure measurements. As a higher viscosity significantly delays the formation of a pressure equilibrium, shaking of the measuring cell is mandatory for ASTM D6377. eravap features a superior cell and shaker design, which allows for a shaking speed of 4.3 cycles per second (red curves), much higher compared to other vapor pressure testers on the market (green and yellow curves). This results not only in a faster measurement but also significantly increases the accuracy and precision. Insufficient shaking or applying a static measuring time can lead to lower values with a bias of up to 10 kPa (1.5 psi).

An excellent e-learning presentation on this topic based on the basics of vapor pressure testing and sampling and testing is provided by the CCQTA on their website >>

scroll to see more images

gallery controls

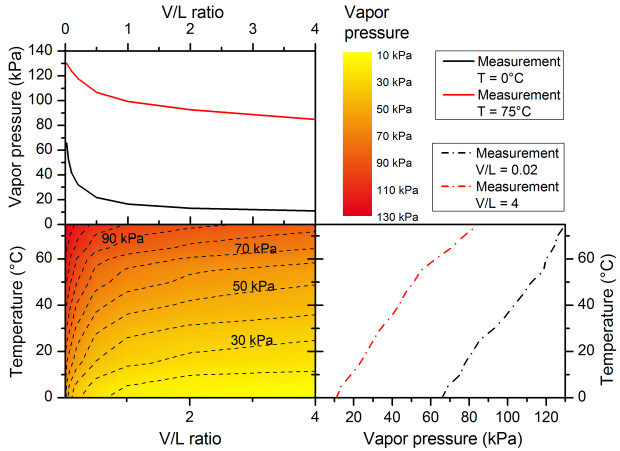

V/L and temperature influences

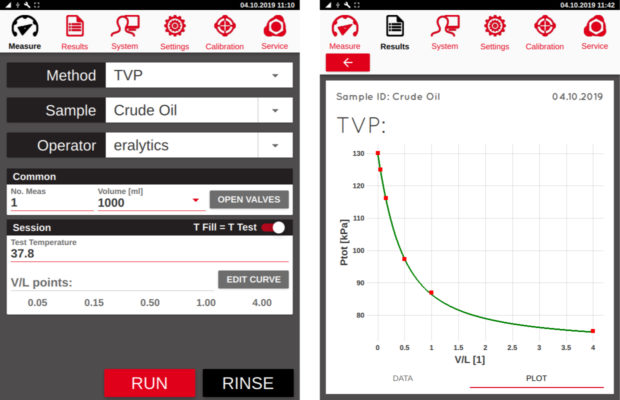

The graph on the side shows the influence of the V/L ratio and the temperature on crude oil vapor pressure testing.

Measuring at the standard conditions of V/L = 4 and T = 37.8 °C the vapor pressure of the sample crude was approximately 40 kPa. At a V/L ratio of 0.02 found in rail cars, trucks or ships already gives a vapor pressure of around 100 kPa. Assuming that this storage tank stands in bright sunlight heating its content to a temperature of 60 °C the vapor pressure rises even further to 120 kPa.

The more light ends the transported crude contains the higher these effects will get. This highlights the importance to measure the crude’s vapor pressure under realistic conditions.

HVM – High viscosity module

eralytics‘ high viscosity module also allows the measurement of highly viscous samples. By heating the inlet, the outlet, and all connecting tubes as well as the inlet assembly up to 70 °C, this optional HVM module makes eravap the perfect analyzer for challenging samples like fuel oil or heavy crudes.

eravap crude directly draws up the sample into the measurement chamber by a piston. Sample take-up of more viscous samples naturally takes a longer time until a viscosity where it becomes impractical. Heating up the sample prior to the introduction reduces the viscosity and the filling procedure speeds up.

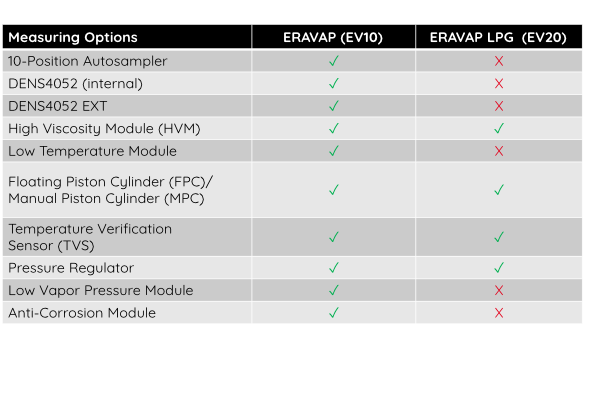

eravap – Unique measuring options

The Vapor Pressure Tester eravap is available in two models. eravap (EV10) for vapor pressure testing of all kinds of liquids up to a max. vapor pressure of 1000 kPa (145 psi) and eravap lpg (EV20) for vapor pressure testing of LPG’s featuring an extended pressure range of up to 2000 kPa (290 psi). To complete your range of applications, eralytics offers a variety of unique measuring options for both eravap models. Get an overview of the unique measuring options of eravap here >>

ASTM D6377 and CCQTA recommendations

ASTM D6377 allows using a wide range of different parameters for crude oil vapor pressure testing. Thus it can be tailored to fit the parameters for most conditions. Studies by the Canadian Crude Quality Technical Association (CCQTA), however, showed that the thermal expansion of the samples makes measurements at very low V/L ratios difficult. CCQTA prefers to analyze the V/L ratio curves at a specific temperature to judge the crude oil.

eralytics’ found a solution for the thermal expansion issue in eravap crude and therefore can measure accurate crude oil vapor pressures at V/L = 0.02. Additionally, curve measurement programs at various V/L ratios are available, including the TVP method (True vapor pressure) which calculates the theoretical VPCR at V/L = 0. This makes eravap crude the ideal choice for crude oil measurement applications.

Application video: eravap – Crude oil testing at its best

Watch eralytics latest application video and convince yourself how we set the benchmark for Vapor Pressure + Density testing of crude oil combining eravap with eralytics revolutionary density meter module DENS4052 and our new piston-cylinder eravap MPC.

Technical Specifications

- Available Test Methods

- ASTM D5188, D5191, D6377, D6378, D6897, EN13016-1, EN13016-2, EN13016-3 ,IP394, IP409, IP481, JIS K2258-2, SHT 0769, SHT 0794, SN/T 2932, GOST 52340

freely programmable methods

EPA / CARB / US Military & NATO reference methods, TVP measurement

VP-V/L Speed TestTM – Combined T(V/L) and vapor pressure measurement - Correlation to…

- ASTM D323, D1267, D2533, D4953, D5190, D5482, D2879 (optional low vapor pressure extension)

- Fuel Specifications

- ASTM D910, D1655, D1835, D4814, D6227, EN 228

- Temperature Range

- 0 °C to 120 °C (32 °F to 248 °F) with Peltier technology. No external cooling is required.

-20 °C to 120 °C (-4 °F to 248 °F) with additional low temperature upgrade (EV01-COOL). External cooling is required.

Extrapolated range: -100 °C to 300 °C (-148 °F to 572 °F) - Temperature Stability

- 0.01 °C (0.02 °F)

- Internal Density Meter Module (Option)

- Density Accuracy: 0.00005 g/cm³

Density Repeatability: 0.00001 g/cm³

Density Resolution: 0.00001 g/cm³

Density Range: 0 – 3 g/cm³

Density Temperature Range: 10 °C to 40 °C (50 °F to 104 °F)

Temperature Accuracy: 0.02°C (0.04°F)

Oscillating Tube: Hastelloy (Patent: US 11,630,044)

Bubble Detection: FillingProofTM – automated bubble detection and bubble quantification (Patent: US 11,493,417 B2)

Full range viscosity correction (Patent: AT523471 A1)

Weight: 1.0 kg (2.2 lb) additional to ERAVAP

The module is suitable for liquids with a boiling point above atmospheric conditions. - Pressure Range

- 0 kPa to 1 000 kPa (0 psi to 145 psi)

- Pressure Units (selectable)

- hPa, kPa, psi, mmHg, Torr, at, atm

- Pressure Resolution

- 0.01 kPa (0.0014 psi)

- Vapor / Liquid Ratio

- Variable from 0.02/1 to 100/1

Single-, multi-point and curve measurements - Precision

- Repeatability: r ≤ 0.15 kPa (0.022 psi) / Cyclopentane @ 37.8°C

Reproducibility: R ≤ 0.50 kPa (0.073 psi) - Available Extension Modules

- EV01-COOL: Low temperature module (-20 °C – 120 °C / -4 °F – 248 °F)

EV01-VISC: High viscosity module (Heated inlet and outlet up to 70 °C / 158 °F)

EV01-VPL: Low vapor pressure module (r = 0.1 kPa; pressure resolution = 0.01 kPa) - Sample Introduction

- Automated via built-in piston

Automated sample filtration through a reuseable 80 µm mesh filter

No external vacuum pump is required - Sample Volume

- 1 mL (2.2 mL per rinsing cycle)

- Measurement Time

- 5 minutes for a standard measurement

- Cleaning

- By next sample or solvent

After crude oil samples cleaning with Toluene is advised - Measuring Chamber

- Nickel-plated aluminum chamber

- Display

- Industry proven 8.4” color touch screen

- Languages

- English, German, French, Spanish, Russian, Chinese

Additional langages available upon request - Interfaces

- Built-in PC with Ethernet, USB and RS232 interfaces

Wifi via external USB dongle

Direct LIMS connectivity via LAN, output to printer or PC as CSV or PDF

Optional input by external keyboard, mouse and barcode reader - Remote Control

- Remote service capability via Ethernet interface

- PC Software

- erasoft RCS – remote control Windows® software for multi-instrument remote control, convenient data transfer, viewing spectra and result analysis

- Result Database

- Over 100,000 detailed test reports stored in internal memory

DVPE, RVPE, PABS, PGAS, PTOT, ASVP & AVP

Results can be marked for hazy appearance

Graphical view of curve measurements - Alarm Tracking

- All alarm messages are stored in the database together with the result

- Automated Calibration Routine

- 10-point probe offset correction table, calibration history tracking, substance calibration, self-diagnostics

- Autosampler

- Optional 10-position autosampler – directly attached

- Operating Conditions

- Temperature range 0 °C to 50 °C

Humidity up to 90% RH, non-condensing - Power Requirements

- Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available - Model Number

- EV10

- Dimensions & Weight

- (W x D x H) = 29.1 x 32.9 x 34.8 cm (11.5 x 12.9 x 13.7 in) / 9.1 kg (20.1 lb)

Downloads

- eravap Brochure English

- eravap Brochure Spanish

- eravap Brochure Portuguese

- eravap Brochure French

- eravap Brochure German

- eravap Brochure Chinese

- Datasheet: eravap for Crude Oil English

- Datasheet: eravap Manual Piston Cylinder English

- Application Note: Combining Vapor Pressure and Density

- Datasheet: 10-Position Autosampler English

- Application Note: Why higher shaker speed improves accuracy of ASTM D6377

- Datasheet: erasoft RCS English

- White Paper: Crude oil vapour pressure testing: Why a higher shaker speed improves the accuracy of measurement