eravap

The all-round vapor pressure tester.

With unmatched precision, speed and versatility eravap is the instrument of choice for vapor pressure testing of e.g. gasoline, crude oil, LPG, solvents, fragrances or aqueous solutions in full compliance with the latest international standards. With eralytics ultra-light temperature-controlled U-tube density meter module DENS4052 (patent), eravap offers even more: simultaneous measurement of vapor pressure and density in a single, portable analyzer.

360° View

Unmatched performance

eravap is a compact, highly precise, yet easy to use vapor pressure tester. It is known for vapor pressure testing with unmatched precision, speed and versatility over the widest available temperature range from -20 °C to 120 °C (4 °F to 248 °F) on the market. A small footprint and the true portability even with an attached 10-position autosampler make it the ideal choice for stationary and mobile laboratories.

The California Air Resource Board (CARB) relies on the unrivaled precision of eravap as well as the U.S. EPA who uses eravap as their reference instrument for vapor pressure testing. Additionally eravap is field proven by the US Army with close to 100 installations in their mobile laboratories around the world.

ERAVAP 2-in-1: Simultaneous measurement of VAPOR PRESSURE + DENSITY with a single, portable analyzer

A ground-breaking innovation for eravap is the optional combination with eralytics temperature-controlled U-tube density meter module DENS4052. This integrated ultra-light (< 1 kg!) density meter module (patented) offers density measurements in full compliance with ASTM D4052 & ISO 12185 (r = 0.00001 g/cm3).

eravap is now the only vapor pressure tester on the market which allows for simultaneous measurements of two parameters listed in international fuel specifications like ASTM D4814 and EN 228 in a single analyzer, namely the vapor pressure of gasoline according to ASTM D5191 and the density of gasoline, diesel or jet fuel according to ASTM D4052. Its portable and rugged design makes eravap the perfect solution for mobile laboratories, terminals, and field use.

For deeper insights into the simultaneous measurement of vapor pressure and density please download the latest application note “Combining Vapor Pressure & Density”.

scroll to see more images

gallery controls

Unique X-oscillating metal U-tube design

The optional density meter module DENS4052 made from the special metal Hastelloy is based on an innovative X-oscillating U-tube where only the straight tubes of the U-tube are vibrating towards each other. In contrast to eralytics x-oscillating U-tube, traditional glass U-tube density meters oscillate in the Y-mode, requiring a heavy counterweight which makes them sensitive against external shocks and vibrations. eralytics’ innovative X-oscillating metal U-tube design is highly resistant against shocks and vibrations and makes it perfectly suitable for the measurement of all kinds of sample types also in the harshest conditions like directly in the field.

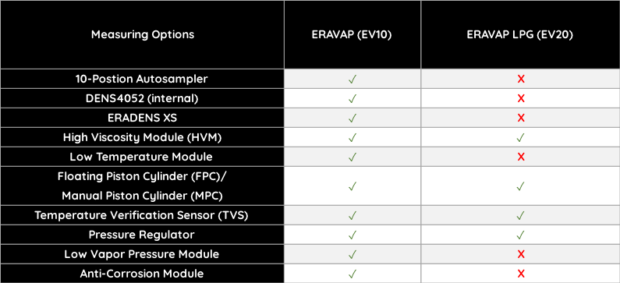

ERAVAP – Unique measuring options

The Vapor Pressure Tester eravap is available in two models. eravap (EV10) for vapor pressure testing of all kinds of liquids up to a max. vapor pressure of 1000 kPa (145 psi) and eravap for lpg (EV20) for vapor pressure testing of LPG’s featuring an extended pressure range of up to 2000 kPa (290 psi). To complete your range of applications, eralytics offers a variety of unique measuring options for both ERAVAP models. Get an overview of the unique measuring options of eravap here >>

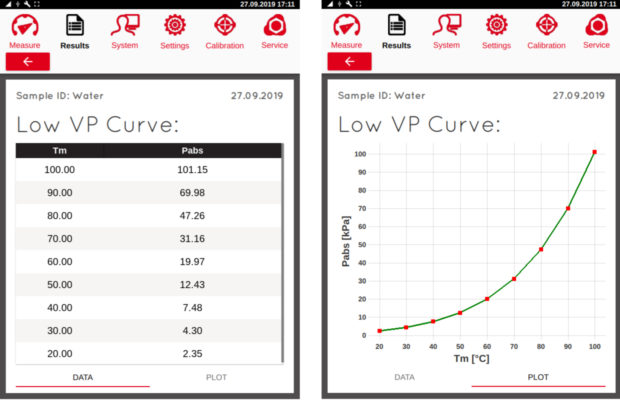

Low vapor pressure module

With eralytics optional LowVP Module (r<0.1 kPa) the measurement of low vapor pressure substances, like solvents or chemicals for MSDS purposes (material safety data sheets) or other official regulations (e.g. REACH) is an easy task. This method is based on the triple expansion method ASTM D6378 using eravap’s built-in high-performance shaker to ensure complete thermodynamic equilibrium at each expansion step, leading to an excellent correlation to the established but manual and time-consuming isoteniscope method ASTM D2879.

TVS™ – Temperature verification sensor for ASTM D5191 testing

One more great feature for eravap is the TVS™ – ASTM D5191 Temperature Verification Sensor (patented) for high precision vapor pressure testing of gasoline. This all-new temperature sensor allows easiest monitoring of the temperature directly in the sample container, featuring an immediate check of the sample preparation even before the actual measurement starts. TVS™ enables the specification of upper (and lower) temperature limits triggering an automatic warning, if the sample temperature does not match the requirements. Thus TVS™ is a very efficient tool helping you to save time and money while improving the quality control in your testing lab. Watch our latest video to get an overview of how the Temperature Verification Sensor TVS™ for eravap works: TVS Operation Video

scroll to see more images

gallery controls

Maximum precision & accuracy

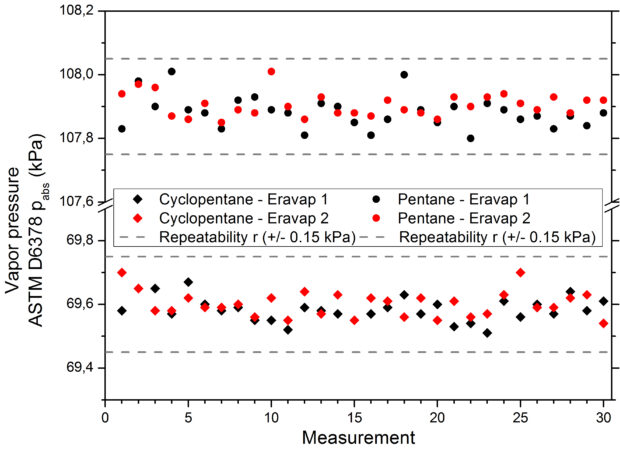

Recent improvements in the design of eravap led to an improved repeatability and reproducibility for vapor pressure testing. With a repeatability of only r ≤ 0.15 kPa and a reproducibility of R ≤ 0.50 kPa for ASTM D5191 and D6378 reference materials at 37.8 °C (100 °F) it clearly outperforms the precision statements of its own ASTM standards. Using ASTM D6378 instead of D5191 for vapor pressure testing additionally eliminates any operator bias caused by incorrect sample preparation needed only for ASTM D5191.

Please reference the graph for latest repeatability measurements of the latest eravap generation using cyclopentane and pentane at 37.8°C (100 °F).

scroll to see more images

gallery controls

Outstanding design

With its quality-centric design eravap was not only designed for highest precision but also for highest durability. The self-lubricating piston and the powerful Peltier elements are the instrument’s centerpiece. It is built for highest sample throughput rates at minimum maintenance. Furthermore, recalibration of the instrument can be performed without any special tools or disassembling the unit.

eralytics patent pending Pure SamplingTM technology minimizes the possiblity of cross contamination between measurements.

Range of applications

The area of applications ranges from freely programmable test methods for R&D labs to push-button simplicity. With its extended temperature range from -20 °C to 120 °C (4 °F to 248 °F) and V/L ratios ranging from 0.02/1 to 100/1 it can cope with the most difficult measurement scenarios as well as with routine analysis. Vapor pressure testing of up to 1000 kPa is possible. In combination with a 12 V DC adapter it can be even run by a vehicle battery, allowing vapor pressure testing in the field.

With its innovative design eravap is capable of measuring gasoline, oxygenated gasoline as well as any other solvent or even polymers. It is used worldwide by refineries, terminals, oil and pipeline companies as well as authorities and independent laboratories.

Option: 10-position autosampler for high sample throughput

eralytics’ 10-position autosampler is an optional accessory for the vapor pressure tester eravap. The 10-position autosampler is directly attached to the instrument allowing it to conveniently connect up to 10 samples simultaneously. It is the perfect solution for higher sample throughput and even more efficiency. All instruments maintain their portability, even with the 10-position autosampler attached.

.

High viscosity module

eravap already covers a wide range of applications with its standard configuration. However, if the viscosity of the samples increases it gets more difficult to draw them into the measurement cell. In such cases heating up the sample prior to introduction helps. During the measurement the sample sitting in the tubes will cool down potentially blocking them after the measurement.

eravap’s high viscosity extension heats the inlet and outlet as well as all transfer tubes up to 70 °C. The temperature is regulated to a defined value set in the measurement menu of the instrument. Using this module further extends the applicability of ERAVAP to a larger range of samples.

Measurement procedure

Beside sample preparation according to the relevant standards, just four easy steps are needed for high quality vapor pressure testing:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters when necessary

- Place the sample beside the analyzer and put the tubing inside the sample

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and piston position, as well as the temperature and pressure within the measurement cell. The resulting vapor pressure is calculated according to the relevant standards and displayed.

scroll to see more images

gallery controls

eravap feature video

- Unmatched temperature range, precision, speed and versatility

- Temperature range from -20 °C to 120 °C (-4 °F to 248 °F)

- Large variety of international standards and correlation methods available

- Pure SamplingTM valve technology minimizes any cross-contaminations

- On-screen quality control mode

- Easy measurement of gasoline, crude oil, LPG and solvents

eravap operation video

Watch this video to get an overview on the standard operation of eravap: From installation to measurement and some extended measuring options.

Technical Specifications

- Available Test Methods

- ASTM D4052, D5188, D5191, D6299 (QC charts), D6377, D6378, D6897, EN13016-1, EN13016-2, EN13016-3, IP394, IP409, IP481, JIS K2258-2, SHT 0769, SHT 0794, SN/T 2932, GOST 52340; freely programmable methods; EPA / CARB reference methods, US D.O.T, RCRA, NAVY, NATO approved, TVP measurement VP-V/L Speed TestTM – Combined T(V/L) and vapor pressure measurement

- Correlation to…

- ASTM D323, ASTM D1267, ASTM D2533, ASTM D4953, ASTM D5190, ASTM D5482, ASTM D2879 (optional low vapor pressure extension)

- Fuel Specifications

- ASTM D910, ASTM D1655, ASTM D1835, ASTM D4814, ASTM D6227; EN 228

- Temperature Range

- 0 °C to 120 °C (32 °F to 248 °F) with Peltier technology. No external cooling is required.

-20 °C to 120 °C (-4 °F to 248 °F) with an additional low-temperature upgrade (EV01-COOL). External cooling is required.

Extrapolated range: -100 °C to 300 °C (-148 °F to 572 °F) - Temperature Stability

- 0.01 °C (0.02 °F)

- Pressure Range

- 0 kPa to 1 000 kPa (0 psi to 145 psi)

- Pressure Units (selectable)

- hPa, kPa, psi, mmHg, Torr, at, atm

- Pressure Resolution

- 0.01 kPa (0.0014 psi)

- Vapor / Liquid Ratio

- Variable from 0.02/1 to 100/1 (Method dependend)

- Precision

- Repeatability:

r ≤ 0.10 kPa (0.015 psi) / n-Pentane at 20°C (ASTM D6378)

r ≤ 0.15 kPa (0.022 psi) / Cyclopentane at 37.8°C (ASTM D6378)

Reproducibility:

R ≤ 0.20 kPa (0.029 psi) / n-Pentane at 20°C (ASTM D6378)

R ≤ 0.50 kPa (0.073 psi) / Cyclopentane at 37.8°C (ASTM D6378) - QC Mode

- Built-in quality control mode including on-screen QC charts (ASTM D6299)

- Internal Density Meter Module (Option)

- Density Accuracy: 0.00005 g/cm³

Density Repeatability: 0.00001 g/cm³

Density Resolution: 0.00001 g/cm³

Density Range: 0 – 3 g/cm³

Density Temperature Range: 10 °C to 40 °C (50 °F to 104 °F)

Temperature Accuracy: 0.02°C (0.04°F)

Oscillating Tube: Hastelloy (Patent: US 11,630,044)

Bubble Detection: FillingProofTM – automated bubble detection and bubble quantification (Patent: US 11,493,417 B2)

Full range viscosity correction (Patent: AT523471 A1)

Weight: 1.0 kg (2.2 lb) additional to ERAVAP

The module is suitable for liquids with a boiling point above atmospheric conditions. - Available Extension Modules

- EV01-COOL: Low-temperature module (-20 °C to 120 °C / -4 °F to 248 °F)

EV01-VISC: High viscosity module (Heated inlet and outlet up to 70 °C / 158 °F)

EV01-VPL: Low vapor pressure module (r = 0.1 kPa; pressure resolution = 0.01 kPa) - Sample Introduction

- Automated via built-in piston

Automated sample filtration through a reuseable 80 µm mesh filter

No external vacuum pump is required - Sample Volume

- 1 mL (2.2 mL per rinsing cycle)

- Measurement Time

- 5 minutes for a standard measurement

- Cleaning

- By next sample or solvent

- Measuring Chamber

- Nickel-plated aluminum chamber

- Display

- Industry proven multilingual 8.4” color touchscreen

- Languages

- English, German, French, Spanish, Russian, Chinese

Additional langages available upon request - Interfaces

- Built-in PC with Ethernet, USB and RS232 interfaces

Wifi via external USB dongle

Direct LIMS connectivity via LAN, output to printer or PC as CSV or PDF

Optional input by external keyboard, mouse and barcode reader - Remote Control

- Remote service capability via Ethernet interface

- PC Software

- erasoft RCS – remote control Windows® software for multi-instrument remote control, convenient data transfer, viewing spectra and result analysis

- Result Database

- Over 100,000 detailed test reports stored in internal memory

DVPE, RVPE, PABS, PGAS, PTOT, ASVP & AVP

Results can be marked for hazy appearance

Graphical view of curve measurements - Alarm Tracking

- All alarm messages are stored in the database together with the result

- Automated Calibration Routine

- 10-point probe offset correction table, calibration history tracking, substance calibration

- Autosampler

- Optional 10-position autosampler – directly attached

- Operating Conditions

- Temperature range 0 °C to 50 °C

Humidity up to 90% RH, non-condensing - Power Requirements

- Auto-switching 85-264 V AC, 47-63 Hz, max. 150 W (multi-voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available - Model Number

- EV10

- Dimensions & Weight

- (W x D x H) = 29.1 x 32.9 x 34.8 cm (11.5 x 12.9 x 13.7 in) / 9.1 kg (20.1 lb)

Downloads

- eravap Brochure English

- eravap Brochure German

- eravap Brochure Spanish

- eravap Brochure French

- eravap Brochure Portuguese

- eravap Brochure Chinese

- Application Note: Combining Vapor Pressure and Density

- Datasheet: 10-Position Autosampler English

- Application Note: Temperature Verification Sensor for ASTM D5191 testing

- Datasheet: Temperature Verification Sensor English

- Datasheet: erasoft RCS English

- Application Note: Why higher shaker speed improves accuracy of ASTM D6377

- White Paper: Crude oil vapour pressure testing: Why a higher shaker speed improves the accuracy of measurement