eravap online

The process vapor pressure tester.

eravap online is the process solution for the already well-proven laboratory vapor pressure tester eravap ensuring lab-grade results. It measures according to the latest standards such as ASTM D6378, D6897, and D6377 including its CCQTA modification. Communication protocols include analog and digital I/Os and Modbus. Multiple sample input streams make it a versatile tool for refineries, blending stations and terminals.

360° View

Standard compliant online vapor pressure testing

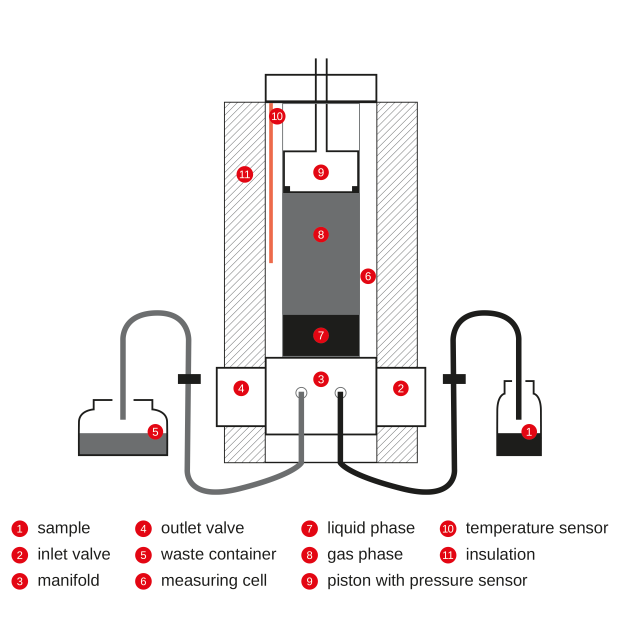

eravap online fully complies with latest vapor pressure standards such as ASTM D6377 for the measurement of crude oil, ASTM D6378 for the measurement of gasoline and ASTM D6897 for the measurement of LPG. All three standards are based on the Mini-Method measurement principle where a piston, containing a pressure sensor, is used to expand the headspace above the liquid. Heating the sample to the measurement temperature at a specified vapor to liquid ratio gives you the vapor pressure of the liquid.

ASTM D6378 offers the advantage over the commonly used ASTM D5191 method, that no sample preparation at all is needed. This fact makes the online vapor pressure testing of gasoline easier and therefore more reliable.

The very same methods are used in our laboratory vapor pressure testers. Therefore no correlation between the online vapor pressure tester and the lab-instrument needs to be established. Both are giving the same results.

Durability for 24/7 operation

eralytics’ R&D team used all know-how and experience gained in seven years of enhancing our laboratory vapor pressure tester during designing eravap online. Self-lubricating gears, continuous oil-level monitoring, ruggedized solenoid valves and many more innovations led to an online vapor pressure tester built to last. This quality-centric design helps to extend service intervals to 6 months or even longer while efficiently avoiding any out-of-control situations.

Minimizing downtime

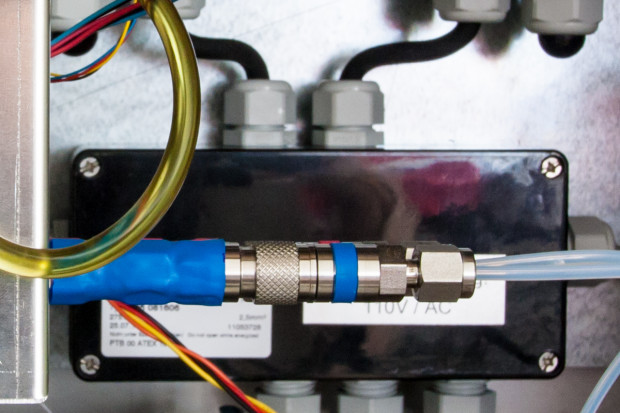

Every eravap online analyzer is delivered with two measurement cells. While one cell is maintained and recalibrated at a safe location the second one is operated inside the explosion proof housing of the analyzer. Swapping them doesn’t require any tools and can be done in less than 5 minutes. Inlet and outlet tubings use quick connectors and only one cable needs to be unplugged. Measurement cells are interchangeable between different eravap online units as all relevant operating parameters are stored directly on the measurement cell itself.

Up to four fluid streams

eravap online handles up to four fluid streams. The configuration of the streams can be fitted to individual needs to include quality control streams as well as cleaning streams for crude oil applications. That way eravap online can be configured to measure the two inlet and the outlet stream of blending applications and still run QC samples now and then.

The eravap online analyzer is equipped with 1/8″ compression fittings for the connection of sample and quality control streams and a 1/2″ compression fitting for the slop line. Using eralytics’ sample conditioning system a 1/2″ fast loop is used. Diameters can be adapted to your needs.

Integrating eravap online into your control system

Integration of the online vapor pressure tester into your process control system can be done in more than one way. MODBUS communication is available using the Ethernet connection or the RS232 / RS485 interface. Additionally four analog outputs (4-20 mA) can be configured freely to output results. Four digital outputs (24 V, max. 500 mA) can be used to communicate alarms, warnings or states to the process control system. Last but not least four digital inputs can be used to start or abort measurements.

Explosion protection

eralytics’ online vapor pressure tester is available in two explosion-proof versions using Pepperl & Fuchs purge-controllers:

- ATEX & IECEx Zone 1

- UL Class 1, Division 1

Both versions use nitrogen as the purge gas compensating leakages, maintaining overpressure inside the analyzer.

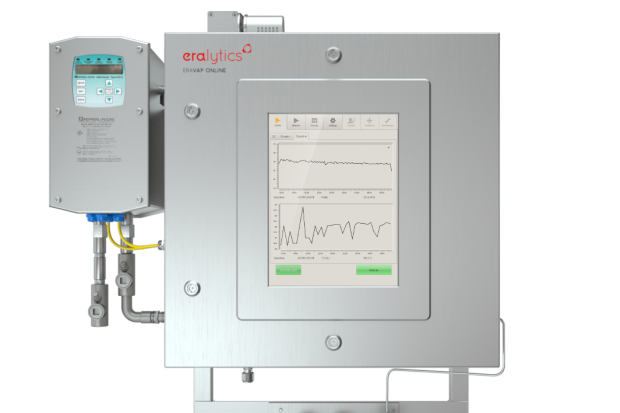

15″ touchscreen for easiest setup

eravap online is equipped with an explosion proof 15″ touchscreen. For the initial setup of the communication protocols, the sample streams and the measurement cycle configuration the big touchscreen is used. During standard operation the predefined measurement schedule is used and data sent over the defined channels. Service personal, however, can use the touchscreen to fully control the analyzer, initiate QC measurements or rinsing cycles if needed. They can also check all relevant system parameters on it.

eravap online feature video

- Measurement of gasoline, crude oil and LPG with up to 4 inlet streams

- Full compliance to ASTM D6377, D6378 and D6897

- Ex-proof housing according to UL Class 1 Division 1 and ATEX/IECEx Zone 1

- Minimum downtime through fast swappable measurement cells

- 15“ touchscreen for intuitive and easiest setup of streams and communication

Technical Specifications

- Available Online Test Methods

- ASTM D6378, D6377, CCQTA version of ASTM D6377,

D5188, ASTM D5191, EN 13016, IP481, GOST 52340 (without air saturation)

Freely programmable methods

EPA/CARB/US Military & NATO reference methods

Fast VP method - Correlation to…

- ASTM D323, ASTM D1267, ASTM D2533, ASTM D4953, ASTM D5190, ASTM D5482, IP 394, IP 409, JIS K2258-2, SHT 0769, GOST 52340

- Measurement Temperature Range

- 0 °C to 120 °C (32 °F to 248 °F)

- Temperature Stability

- 0.01 °C (0.02 °F)

- Pressure Range

- EP01-M: 0 kPa to 1 000 kPa (all applications, e.g. gasoline, crude oil, LPG)

- Pressure Resolution

- 0.01 kPa (0.0014 psi)

- Pressure Units (selectable)

- hPa, kPa, psi, mmHg, Torr, at, atm

- Vapor / Liquid Ratio

- Variable from 0.02/1 to 100/1

- Precision

- Repeatability: r ≤ 0.15 kPa (0.022 psi)

Reproducibility: R ≤ 0.50 kPa (0.073 psi) - Cycle Time

- 7 minutes (typically, depending on sample condition)

- Inlet Streams

- Up to 4 inlet streams (sample, quality control, purging)

- Connections

- Analyzer inlet 1/8″ (gasoline, LPG) or 1/4″ (crude oil) compression fittings

Sample conditioning system and waste connection 1/2″ compression fittings - Sample Volume

- 1 mL (5 mL per rinsing cycle)

- Process Stream Requirements

- Analyzer: 200 kPa to 300 kPa (without sample conditioning system)

Sample conditioning system: 300 kPa to 7 000 kPa (min. flow 5.7 L/min) - Interfaces

- Modbus via Ethernet

4x analog output (4 mA – 20 mA)

4x digital output (24 V, max. 500 mA per port)

4x digital input (24 V) - Explosion Proof

- UL Type X or ATEX / IECEx purging system (purge gas Nitrogen)

- Display

- Industry proven 15″ color touchscreen

- Automated QC Routine

- Built-in quality control tracking

- RCS Remote Control Software

- Windows® software for remote control from safe areas

- Ambient Operating Temperature

- -10 °C – 40 °C (14 °F – 104 °F)

- Power requirements

- 100 – 240 V AC, 50/60 Hz, 8 Amp

- Dimensions & Weight

- Analyzer: 80.0 x 32.0 x 70.0 cm (31.5 x 12.6 x 27.6 in) / 60 kg (132.3 lb)

Sample conditioning system (per stream): 30.0 x 85.0 x 15.0 cm (12 x 34 x 0.6 in) / 15 kg (33 lb)