eraflash X

The petroleum flash point tester.

eraflash X is the future-proof replacement for ASTM D93 Pensky-Martens testers. Tailored for the petroleum industry all kinds of liquids can be tested over the wide temperature range of 18 °C to 370 °C using only 2 mL of sample. The full compliance with the latest flash point standard ASTM D7094 brings 100% safety, unrivaled speed as well as best in class precision to your laboratory.

360° View

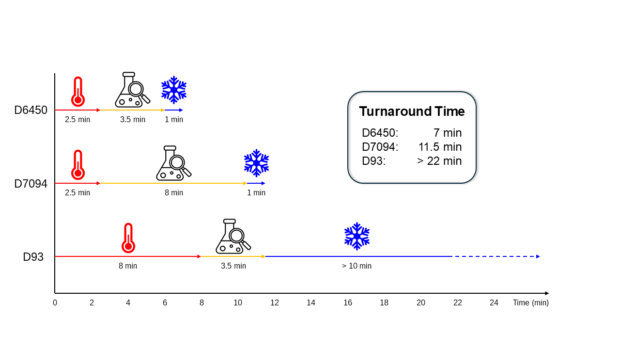

Xtra fast: Shortest turnaround times

eraflash X features eralytics’ patented PBT – Peltier Boost Technology® , which allows for unrivalled heating and cooling power and a wide temperature range of 18 °C to 370 °C (64 °F to 689 °F). In combination with the small sample volume, significantly shorter turnaround times are achieved compared to all other flash point testers on the market. With eraflash X, a typical ASTM D7094 diesel measurement is performed in less than 12 min, which is two times faster than a traditional D93 Pensky-Martens test. This enables up to 5 complete flash point tests per hour with eraflash X.

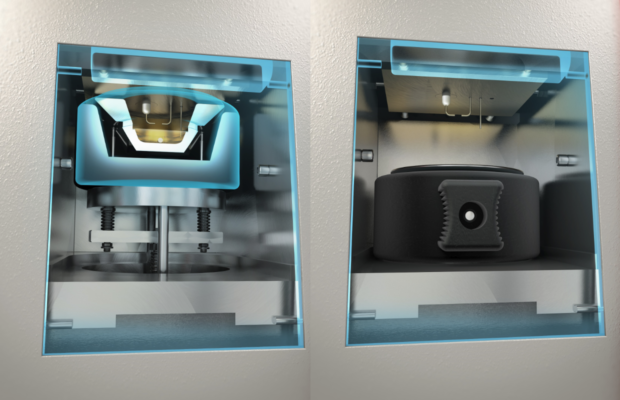

Xtra safe: 100% safety in the laboratory

Based on the inherently safe CCCFP design, eraflash X measures the flash point through pressure changes inside a continuously closed cup. In contrast to Pensky- Martens instruments, the ERAFLASH flash point tester series does not use an open flame, eliminating the risk of fire in your laboratory. Instead, 2 pins create an electric arc that is used to ignite the sample inside a closed chamber. Due to the small sample volume (2 ml) and the resulting low oxygen amount within the closed cup, the flame is automatically extinguished after ignition. The pressure increase in the closed cup following the ignition is used for the detection of the flash point. A pressure increase of ≥ 20 kPa is defined as a flash point by the method.

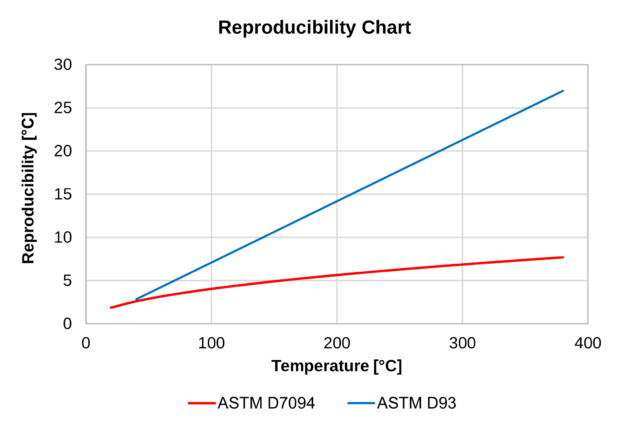

Xtra precise: Best precision in class

eraflash X is the most precise flash point tester for all kinds of petroleum liquids. As proven by the latest ASTM interlaboratory flash point study, ASTM D7094-23 offers best in class precision over the widest temperature range and for the widest range of samples. ASTM D7094 is already listed in the following fuel specifications as a valid flash point test method and a future-proof replacement for ASTM D93 Pensky-Martnes testers:

ASTM D396 – Fuel Oil

ASTM D975 – Diesel Fuel

ASTM D2880 – Gas Turbine Fuel Oils

ASTM D3699 – Kerosine

ASTM D7467 – Diesel Fuel Oil & Biodiesel Blends

Xtra easy: Straigthforward measurement and sample handling

In contrast to 75 mL for a traditional ASTM D93 Pensky-Martens flash point test, ASTM D7094 requires only 2 mL of sample. Flash point testing with eraflash X does not require any special sample preparation, and filling and cleaning of the small sample cup is completed in a matter of seconds. Practically no waste of potentially hazardous materials is generated, which leads to significantly lower costs per measurement.

Measurement procedure

Just four easy steps are required for a safe flash point testing at maximum precision:

- Enter sample ID and operator name

- Select the measurement standard and add additional parameters (e.g. expected flash point)

- Fill the sample cup with sample, place the sample cup inside the measurement chamber, and close the door

- Press the RUN button

The instrument now visualizes the measurement procedure on the screen showing the sample and oven temperature as well as pressure gauge displaying the pressure increase after ignition. After the measurement the flash point temperature is corrected for the atmospheric pressure and rounded to the next 0.5 °C. The result will be saved in the corresponding result file.

scroll to see more images

gallery controls

Technical Specifications

- Test Methods

- ASTM D7094, IP 620

- Fuel Specifications

- ASTM D396, D975, D2880, D3699, D7467

- PBT – Peltier Boost Technology®

- High speed heating and cooling

- CPT – Contamination Prevention Technology™

- Advanced electrode protection and self-cleaning ignition system to minimize cleaning and maintenance

- QuickCal™

- In-situ calibration with eralytics unique calibration cups without the need of dismantling the instrument

- Fuel Dilution Program

- Automatic fuel dilution measurement for the analysis of used engine oils

- Temperature Range

- 18 °C to 370 °C (64 °F to 689 °F)

- Temperature Stability

- 0.1 °C (0.2 °F)

- Turnaround Time

- up to 5 tests per hour

- Sample Volume

- 2 mL

- Reproducibility

- R = 3.2 °C for diesel fuel at 60 °C (ASTM D93: R = 4.3 °C)

R = 5.6 °C for lube oil at 200 °C (ASTM D93: R = 14.2 °C) - Result Database

- Over 100 000 detailed test reports stored

- PC Software

- ERASOFT RCS – Windows® software for convenient data transfer and result analysis

- Remote Control

- Remote service capability via Ethernet

- Interfaces

- Built-in PC with Ethernet, USB, and RS232 interfaces, Wi-Fi via USB dongle

Direct LIMS connectivity via LAN and output to printer or PC - Display

- Industry proven 5.7“ multilingual color touchscreen

- Languages

- English, German, French, Spanish, Japanese, Chinese; additional langages available upon request

- Power Requirements

- Auto-switching 85 – 264 V, AC 47 – 63 Hz, max 150 W, Field application: optional 12 V DC adapter

- Operating Conditions

- Temperature range 10°C to 40°C, Humidity up to 90% RH, non-condensing

- Dimensions & Weight

- W x D x H = 19.6 x 20.4 x 31.7 cm (7.7 x 8.0 x 12.5 in) / 7.2 kg (15.9 lbs)