eracheck eco

The CFC-free oil-in-water tester.

eracheck eco combines the inherent advantages of IR methods, like high speed and sub-ppm precision with the use of the CFC-free and low-cost extraction solvent cyclohexane. eracheck eco is the only analyzer on the market being fully compliant with the latest standard ASTM D8193. The cost-efficient and eco-friendly measurement technology provides the most economical alternative for oil-in-water testing on the market.

360° View

ASTM D8193

ASTM D8193 describes a direct IR transmission measurement of oils and greases in the extraction solvent. The method does not require any solvent evaporation like gravimetric or solventless IR methods and therefore allows the measurement of all fractions of the sample, including the light ends, with sub-ppm precision (repeatability SD: 0.2 mg/L oil-in-water). Compared to GC methods that do not detect fractions eluting outside the defined time window, ASTM D8193 enables a more complete fraction of extracted hydrocarbons much faster and easier.

User-specific calibrations

With eracheck eco’s easy-to-operate design and its intuitive software, user-specific calibrations or correlations are easily created. This enables excellent correlations to gravimetric methods (EPA 1664A) and gas chromatography (e.g. ISO 9377-2 (mod) OSPAR).

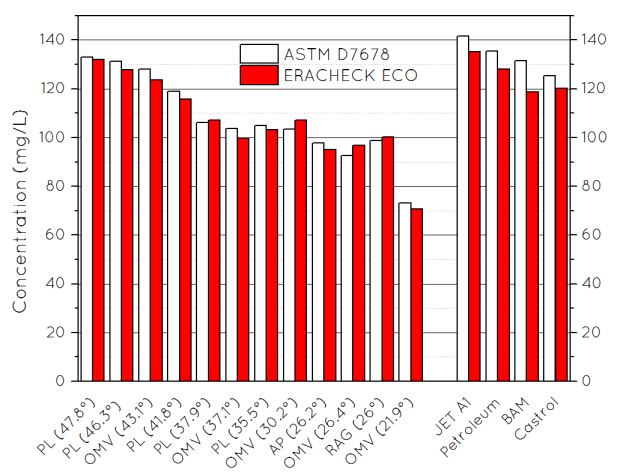

With the calibration defined in ASTM D8193, the correlation to other IR methods (ASTM D7066, ASTM D7678 etc.) is also readily assured. A direct measurement of the extract results in the total oil and grease (TOG) concentration, whereas filtration over a disposable Florisil® solid phase extraction cartridge attached to the inlet of the instrument removes the polar components resulting in the total petroleum hydrocarbon (TPH) concentration.

Maximum connectivity

eracheck eco is a compact stand-alone analyzer equipped with an industry proven 8.4″ multilingual color touchscreen and a built-in industrial PC. State-of-the-art connectivity options like LAN, 5 x USB and RS232 allow you to attach the latest printers, keyboards and bar code scanners or to connect the instrument to any Laboratory Information Management System (LIMS). Furthermore, the fully automated measurement enables the use of eralytics’ directly attached 10-position autosampler for higher sample throughput and even more efficiency.

Option: 10-position autosampler for high sample throughput

eralytics’ 10-position autosampler is an optional accessory for the oil-in-water tester eracheck eco. The 10-position autosampler is directly attached to the instrument allowing it to conveniently connect up to 10 samples simultaneously. It is the perfect solution for higher sample throughput and even more efficiency. All instruments maintain their portability, even with the 10-position autosampler attached. Read more >>

Measurement procedure

- Extract the water sample with cyclohexane: Typically 900ml water are extracted with 50ml cyclohexane

- Select the method you want to use: TPH or TOG

- Select the correct calibration

- Enter the name of the sample and the name of the operator

- Press the RUN button

- The instrument runs a background measurement of pure cyclohexane

- The instrument measures your extracted sample

eracheck eco guides you through the measurement procedure. The liquid volumes have to be entered depending on the actual volumes used for the extraction of the sample.

scroll to see more images

gallery controls

Your features at a glance

- Ecologically friendly and economical oil-in-water testing

- CFC-free measurement using cyclohexane for extraction

- TPH and TOG measurements

- Fully compliant with ASTM D8193

- Excellent correlation to EPA 1664, ISO 9377-2, ASTM D3921 and ASTM D7678

- Method detection limit (MDL): 0.5 mg/L oil-in-water

eracheck eco operation video

Watch this video to get an overview on the standard operation of eracheck eco: From installation, sample extraction to measurement and some extended measuring options.

Technical Specifications

- Available Test Method

- ASTM D8193

- Correlation to

- Infrared spectroscopy: ASTM D7678, ASTM D3921, D7066; DIN 38409-H18; OSPAR IR method; IP426

Gas chromatography: ISO 9377-2, ISO 9377-2 (mod) OSPAR, ISO 16703; MADEP-EPH; EN 14039

Gravimetry: EPA 1664, EPA 9071; ASTM D4281; ISO 9377-1 - Extraction Method

- External liquid-liquid or solid-liquid extraction

- Extraction Solvent

- Cyclohexane

- Applications

- TOG (Total Oil and Grease) and TPH (Total Petroleum Hydrocarbon)

- Sample Clean-up (TPH)

- Simplified removal of polar substances with eralytics’ disposable Florisil® cartridges

- Sample Volume

- Typically 900 mL water and 50 mL cyclohexane (min. 10 mL solvent required per measurement)

- Measurement Time

- appr. 2 min + 2 min background measurement

- Repeatability (SD)

- Enrichment factor 18 (900:50 mL H2O:Solvent)

0 – 49.9 mg/L: 0.2 mg/L

50 – 299.9 mg/L: 0.5 mg/L

300 – 1 000 mg/L: 1.2 mg/L - Method detection limit (MDL)

- 0.5 mg/L oil-in-water (900:50 mL H2O:Solvent)

18 mg/kg oil-in-soil (20 g:40 mL Soil:Solvent) - Measurement Range

- ASTM D8193: 0-1000 mg/L oil-in-water (900:50 mL H2O:Solvent)

Up to 18 000 mg/L oil-in-water (50:50 mL H2O:Solvent)

Up to 36 000 mg/kg oil-in-soil (20 g:40 mL Soil:Solvent) - Interfaces

- Built-in PC with Ethernet, front and rear USB and RS232 interfaces; Wifi via USB dongle

Direct LIMS connectivity via LAN, output to printer or PC and export as CSV or PDF

Optional input by keyboard, mouse and barcode reader - Display

- Industry proven 8.4″ multilingual color touchscreen

- Remote Control

- Remote service capability via Ethernet interface

- PC Software

- erasoft RCS – remote control Windows® software for multi-instrument remote control, convenient data transfer and result analysis

- Result Database

- Over 100 000 detailed test reports stored in internal memory

- Alarm Tracking

- All alarm messages are stored in the database together with the result

- Power Requirements

- Auto-switching 85 – 264 V AC, 47 – 63 Hz, max. 150 W (multi-voltage power supply)

Field application: 12 V DC (vehicle battery) adapter available - Dimensions & Weight

- (W x D x H) = 29.1 x 32.9 x 34.8 cm (11.5 x 12.9 x 13.7 in) / 9.3 kg (20.5 lb)

Downloads

- eracheck eco Brochure English

- eracheck eco Brochure Spanish

- eracheck eco Brochure French

- eracheck eco Brochure Portuguese

- eracheck eco Brochure Chinese

- Datasheet: 10-Position Autosampler English

- Datasheet: erasoft RCS English

- Article on “Ecological and economical measurement of oil-in-water without compromising accuracy”

- Application Note: ASTM D8193 Oil-in-Water testing: Accuracy & Correlation to EPA 1664

- Application Note: ASTM D8193 vs. ASTM D7678: A comparison between two IR based oil-in-water test methods