eradens X

The smallest D4052 density meter.

eradens X is the world’s smallest and lightest high-precision density meter measuring in full compliance with ASTM D4052 and ISO 12185. Its revolutionary vertically aligned x-oscillating metal U-tube design is extremely reliable and insensitive to toughest ambient conditions, making the density meter eradens X the perfect solution for density testing in stationary as well as in mobile laboratories.

360° View

Xtra easy: Experience effortless measurements with the eradens X density meter

The eradens X features a large, industry-proven color touchscreen that enhances your daily measurement routine with its intuitive user interface. This easy-to-use design ensures efficient operation, even while wearing gloves. The unique top-down sample introduction system makes eradens X equally accessible for both right-handed and left-handed users. Results are conveniently displayed on the large screen, with options to print, export via USB, or transfer directly to a PC or LIMS through an ethernet connection.

Xtra rugged & compact: The robust, portable and compact eradens X density meter for accurate testing

eradens X is built in a corrosion-resistant aluminum housing and has no moving parts. The revolutionary design featuring a vertically aligned x-oscillating metal U-tube makes eradens X an extremely robust and versatile analyzer that is unaffected by shocks and vibrations. It is therefore the perfect solution for highly accurate testing even under extreme conditions.

eradens X is the analyzer with the smallest footprint on the market, still offering maximum ease of use and operator convenience. The compact dimensions and lightweight instrument design offer true portability on-site and require minimum bench space in the lab.

Xtra accurate: Unmatched Precision with x-oscillating metal U-tube technology

With the x-oscillating metal U-tube technology inside, eradens X provides density results with 5-digit precision. eralytics unique full range viscosity correction ensures that the highest possible accuracy is achieved over the wide temperature range of 0 – 100 °C.

eradens X density meter: Ensuring bubble-free filling with innovative FillingProof® Technology

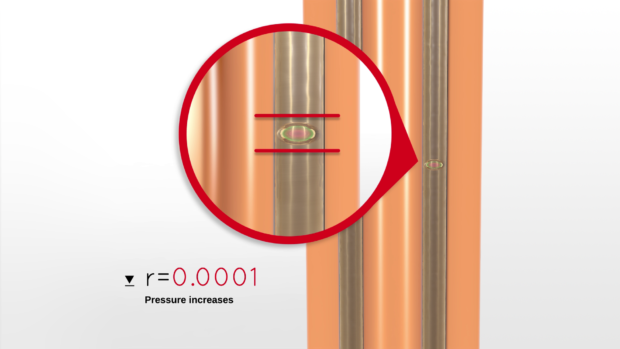

The vertical alignment of the U-tube minimizes the probability of air bubbles getting trapped inside the density cell. For the verification of the bubble-free filling, eralytics has developed FillingProof® (Patent: US 11,493,417 B2). In contrast to error-prone optical methods, the change in the density as a function of applied pressure is used to detect even the smallest bubbles providing reliable results also for non-transparent samples such as crude oil.

scroll to see more images

gallery controls

eradens X density meter: Your features at a glance

- The smallest and lightest D4052 density meter

- Fully compliant with ASTM D4052 and ISO 12185

- Vertically aligned x-oscillating metal U-tube design

- Extremely reliable and robust

- Providing density results with 5-digit precision

- FillingProof® Technology

eradens X operation video

Watch this video to get an overview of the standard operation of eradens X: From installation to measurement – a piece of cake.

Technical Specifications

- Standards

- ASTM D4052, D5002, D5931, ISO 12185

- Density Range

- 0 – 3 g/cm3

- Temperature Range

- 0 °C to 100 °C (32 °F to 212 °F)

- Density Repeatability (SD)

- 0.000005 g/cm3 (according to ISO 5725)

- Density Resolution

- 0.00001 g/cm3

- Temperature Accuracy

- 0.02 °C (0.04 °F)

- Pressure Range

- 0 -10 bar (145 psi) absolute pressure

- Measurement Time

- 15 sec (after temperature equilibration)

- Sample Volume

- 2 mL

- Oscillating Tube

- Hastelloy C276 (Patent: US 11,630,044, AT522941 B1)

- Bubble Detection

- FillingProof®- automated bubble detection and bubble quantification (Patent: US 11,493,417 B2; AT522940 B1)

- Viscosity Correction

- yes – full range correction (Patent: AT523471 A1)

- Tables & Functions

- API, specific gravity, sugar, alcohol, etc, and freely programmable tables

- Special Features

- Integrated fully-automated drying pump, built-in ambient pressure sensor

- Result Database

- Over 100 000 detailed test reports stored

- Remote Service

- Remote service capability via Ethernet

- Interfaces

- Built-in PC with Ethernet, 4 x front and rear USB and RS232 interfaces; Wi-Fi via USB dongle

Direct LIMS connectivity via LAN, output to printer or PC and export as CSV or PDF

Optional input by keyboard, mouse, and barcode reader - Display

- Industry-proven 8.4“ multilingual color touchscreen

- Power Requirements

- 85 – 264 V AC 47- 63 Hz, max 150 W

- Operating Conditions

- 5 °C – 45 °C up to 90 % rel. humidity (non-condensing)

- Dimensions & Weight

- (W x D x H) = 18.0 x 28.6 x 29.3 cm (7.1 x 11.2 x 11.5 in) / 7 kg (15 lb)