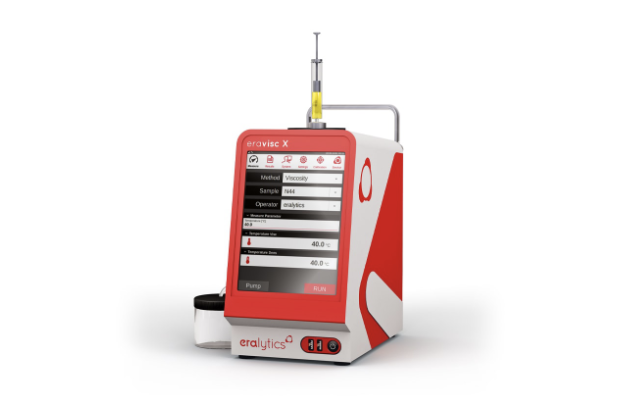

eravisc X

The smallest kinematic viscometer.

eravisc X is the world‘s smallest and most rugged kinematic viscometer measuring viscosity with lab-grade precision meeting ASTM D445 and ASTM D7042. Its revolutionary viscosity cell is combined with eralytics unique x-oscillating metal U-tube density cell. This allows an independent high-precision density measurement in full compliance with ASTM D4052 and ISO 12185.

360° View

Xtra easy & fast

The fully automated measurement of the kinematic viscosity at 40 °C or at 100 °C takes only 1 minute. Results are displayed on the large color touchscreen and can be printed, exported via USB or directly transferred to a PC or LIMS via an Ethernet connection. With its unique sample introduction from the top the viscometer eravisc X is equally easy to operate for right-handed and left-handed persons.

Xtra rugged

The viscometer eravisc X is built in a corrosion-resistant aluminum housing. Its robustness and reliability make it the ideal solution for daily viscosity measurements in the laboratory as well as directly in the field to immediately prove specification or detect contamination, and oil degradation. eravisc X is the perfect solution for highly accurate testing even under extreme conditions.

Xtra accurate & compact

eravisc X’s revolutionary capillary measuring cell is a real game changer for high-precision kinematic viscosity testing at any temperature between 15 °C and 100 °C. Latest Peltier Technology allows for automated, high-speed viscosity index measurement. eralytics unique FillingProof® solution detects even smallest bubbles, ensuring maximum density accuracy. eravisc X is the analyzer with the smallest footprint on the market, still offering maximum ease of use and operator convenience. The compact dimensions and lightweight instrument design offer true portability on-site and require minimum bench space in the lab.

2 in 1: Viscosity & density testing with lab-precision

eravisc X allows for the independent measurements of viscosity and density enabling the simultaneous determination of both values at different temperatures. eralytics unique, dynamic capillary viscosity measurement method determines the flow time of the sample as a function of a rapidly measured pressure. This patented principle combines the advantages of traditional capillary methods with the speed and ease of use of eralytics instruments.

Your features at a glance

- The smallest and most rugged kinematic viscometer

- Lab-grade precision (ASTM D445 and ASTM D7042)

- Measurement of kinematic viscosity at 40 °C or at 100 °C in 1 minute

- Independent high-precision density measurement in full compliance with ASTM D4052 and ISO 12185

- Revolutionary capillary measuring cell

- FillingProof® Technology

Technical Specifications

- Available Test Methods

- Viscosity: Correlation to ASTM D445, D7042, D2270, ISO 3104, ISO 23581

Density: ASTM D4052, D5002, ISO 12185 - Special Operation Modes

- Viscosity Index (40 °C & 100 °C)

Simultaneous Viscosity & Density testing at independent temperatures - Measuring Range

- Viscosity: 1 – 1000 mm2/s | Density: 0 – 3 g/cm3

- Temperature Range

- Viscosity: 15 °C to 100 °C (59 °F to 212 °F) | Density: 0 °C to 100 °C (32 °F to 212 °F)

- Accuracy *

- Viscosity: 0.8 % | Density: 0.00005 g/cm3

- Repeatability (SD)*

- Viscosity: 0.25 % | Density: 0.000005 g/cm3

- Resolution

- Viscosity: 0.01 mm2 /s | Density: 0.00001 g/cm3

- Temperature Accuracy

- 0.02 °C (0.04 °F)

- Measurement Time

- 1 minute

- Sample Volume

- 3 mL

- Bubble Detection

- FillingProofTM – automated bubble detection and bubble quantification

(Patent: US 11,493,417 B2) - Oscillating Tube (Density)

- Hastelloy (Patent: US 11,630,044)

- Viscosity Correction (Density)

- Yes – full range correction (Patent: AT523471 A1)

- Special Features

- Integrated fully-automated drying pump, built-in ambient pressure sensor

- Result Database

- Over 100 000 detailed test reports stored

- Remote Service

- Remote service capability via Ethernet

- Interfaces

- Built-in PC with Ethernet, 4 x front and rear USB, RS232 interfaces, Wi-Fi via USB dongle

Direct LIMS connectivity via LAN, output to printer or PC, and export as CSV or PDF

Optional input by keyboard, mouse, and barcode reader - Display

- Industry-proven 8.4“ multilingual color touchscreen

- Power Requirements

- 85 – 264 V AC 47 – 63 Hz, max 150 W

- Operating Condition

- 5 °C – 45 °C up to 90 % rel. humidity (non-condensing)

- Dimensions & Weight

- (W x D x H) = 18.0 x 28.6 x 29.3 cm (7.1 x 11.2 x 11.5 in) / 8 kg (17.6 lb)

- *Typical values, depending on sample type and temperature and without consideration of the particular uncertainties of reference materials (CRM)