eraspec oil X

The dedicated FTIR for lube oil analysis.

The eraspec oil X is the world’s smallest lab-grade FTIR lube oil analyzer. At the push of a button eraspec oil X delivers a detailed fingerprint of lubricating oils using only 2 mL of sample. Thanks to its rugged and lightweight design, eraspec oil X is the perfect tool for ultra-fast measurements in laboratories, inside mobile labs or even directly in the field. All this is available with outstanding measurement accuracy.

360° View

FTIR fingerprinting of lube oils

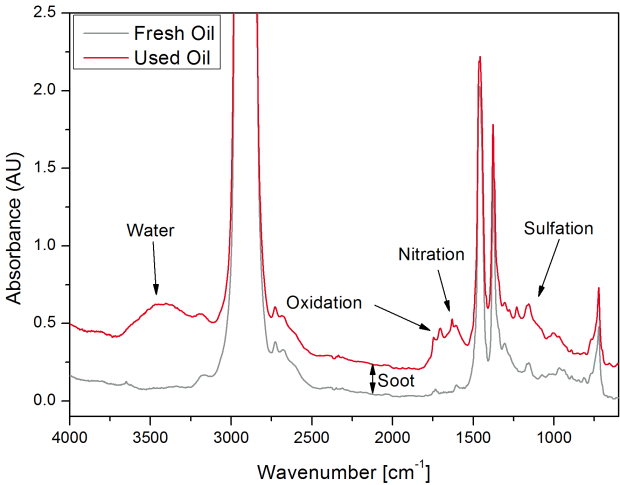

eraspec oil X is the perfect solution for FTIR fingerprinting of lubricating oils, providing a comprehensive composition of any lubricant or base oil. Monitoring oil degradation like oxidation, screening contaminants such as water, and checking levels of antioxidant additives was never easier. The FTIR spectra are saved on the analyzer and can be easily exported for further use.

scroll to see more images

gallery controls

Portable and easy lube oil analysis

eraspec oil X is a lab-grade FTIR spectrometer built inside a lightweight and rugged metal housing making it ideal for on-site lubricating oil analysis. Whether you are testing fresh or used oil, eraspec oil X provides fast and reliable results in the lab as well as in the field. eraspec oil X is factory calibrated and comes with a built-in reference cell that allows for fully automated reference measurements. The measurement itself is fully automated and requires only 2 mL of sample. In less than two minutes eraspec oil X delivers a detailed fingerprint of lubricating oils with highest precision.

Analysis of fresh and used oils

With its modular design the detailed analysis of fresh oils and used oils becomes a simple and straight-forward routine. Important degradation parameters such as oxidation, nitration or sulfation as well as soot or fuel dilution are readily monitored by IR spectroscopy. Additionally, it comes pre-programmed for important antioxidant and wear additives. Evaluation is done according to latest ASTM and DIN standards like ASTM E2412, ASTM D7624 and many more. Both direct trending and spectral subtraction incorporating the fresh oil spectra are readily possible.

eraspec oil X – fast & accurate oil condition monitoring

As part of eralab OCM, eraspec oil X also provides fast & accurate oil condition analysis to support predictive maintenance for

- Contamination detection: Detects contaminants like water, glycol, fuel, or other impurities compromising oil quality

- Oil composition monitoring: Measures oxidation, nitration and sulfation

- Additive depletion: tracks levels of antioxidants and anti-wear additives

scroll to see more images

gallery controls

Measurement procedure

eraspec oil X performs spectral FTIR analysis of lubricants in three easy steps:

- Enter the sample ID, select the oil type and the method

- Fill the sample with a syringe from the top of the analyzer into the measurement cell

- Press the RUN button

The measurement steps are visualized on the display, showing the deflection of the moving mirror of the interferometer. When the measurement is completed the results are displayed and can be printed or exported with a single click.

scroll to see more images

gallery controls

Parameters covered by eraspec oil X

Degradation

| Degradation | Standard | Unit |

|---|---|---|

| Oxidation | ASTM E2412, D7414, JOAP, DIN 51453 | A/cm |

| Nitration | ASTM E2412, D7624, JOAP, DIN 51453 | A/cm |

| Sulfation | ASTM E2412, D7415, JOAP | A/cm |

Additives

| Additives2 | Standard | Unit2, 3 |

|---|---|---|

| ZDDP | ASTM E2412, D7412, JOAP | A/cm, %, wt% |

| Phenolic Antioxidants | ASTM D2668, ASTM D2668, IEC 60666 | %, wt% |

| Aminic Antioxidants | %, wt% | |

| Aromatics | IEC 60590 | % |

2 … Additive depletion in % remaining additive are available only for spectral subtraction measurements.

3 … wt% values are determined by a factory calibration

Contaminants

| Contaminants | Standard | Unit3 |

|---|---|---|

| Soot | ASTM E2412, JOAP, DIN 51452 | A/cm, wt% |

| Water | ASTM E2412, JOAP | A/cm, wt% |

| Ethylene Glycol (Antifreeze) | ASTM E2412, JOAP | A/cm, wt% |

| Diesel Fuel | ASTM E2412, JOAP | A/cm, wt% |

| Gasoline | ASTM E2412, JOAP | A/cm, wt% |

| FAME | wt% | |

| Polyolester | wt% | |

| Phosphate Ester | wt% |

3 … wt% values are determined by an eralytics calibration

Technical Specifications

- Available Test Methods

- ASTM E2412, D2668, D7214, D7412, D7414, D7415, D7418, D7624, D7844, D8340, DIN 51452, DIN 51453, IEC 60590, IEC 60666, JOAP

- Spectrometer Type

- Patented mid-FTIR interferometer

Laser and temperature controlled design - Measurement Cell

- 100 μm path length sample cell, additional built-in reference cell

Optimized dual position cell design for automated reference measurement without solvent - Calibration

- Factory calibration for e.g. soot, water, glycol, antioxidants

- Measurement Principle

- Direct trending: calculation based on the absorption spectrum of the sample at specific wavelengths

Spectral subtraction: fresh oil spectrum used as reference for highest performance and lowest LODs - Measurement Time

- 60 seconds; warm-up time: 30 seconds

- Filling Mode

- Syringe filling

- Sample Viscosity

- Up to 1 000 mm2/s at 20 °C

- Sample Volume

- Minimum 4 mL with sample displacement; minimum 2 mL with intermediate cleaning

- Cleaning

- Rinsing with next sample or solvent

Integrated and replaceable filter to prevent blocking of measurement cell - Interfaces

- Built-in PC with Ethernet, 5x USB-A, 1x USB-B, and RS232 interfaces; Wifi via USB dongle

Direct LIMS connectivity via LAN and output to printer or PC, and export as CSV or PDF

Optional input by keyboard, mouse and barcode reader - Display

- Industry proven 8.4″ multilingual color touchscreen

- Remote Control

- Remote service capability via ethernet inferface

- PC Software

- erasoft RCS – remote control Windows® software for multi-instrument remote control,

convenient data transfer, viewing spectra and result analysis

erasoft OCM software – supports operators in the management, operation and predictive maintenance of technical equipment with a focus on oil condition monitoring - Result Database

- Approx. 30 000 detailed test reports and spectra stored in the internal memory

- Alarm Tracking

- All alarm messages are stored in the database together with the results

- Power Requirements

- 85 – 264 V AC, 47 – 63 Hz, max. 150 W

Field application: 12 V DC vehicle battery, adapter available - Operating Conditions

- 5 °C – 45 °C up to 90 % rel. humidity (non-condensing)

- Dimensions / Weight (W x D x H)

- 18.0 x 28.6 x 29.3 cm (7.1 x 11.2 x 11.5 in) / 7 kg (15.4 lb)